One-button automatic quick service(Quick Service)

1.Automatic cleaning of nitrogen accumulated moisture inside the fuselage

2. Accelerated nitrogen injection solution cream first sweep accelerate work

3.CIP/SIP Nitrogen positive pressure treatments.

Preventing outside moist hot air into the machine body

Internal solution frost hinder operation of the device

Model:Cryodoser S300 and Siemens S7200

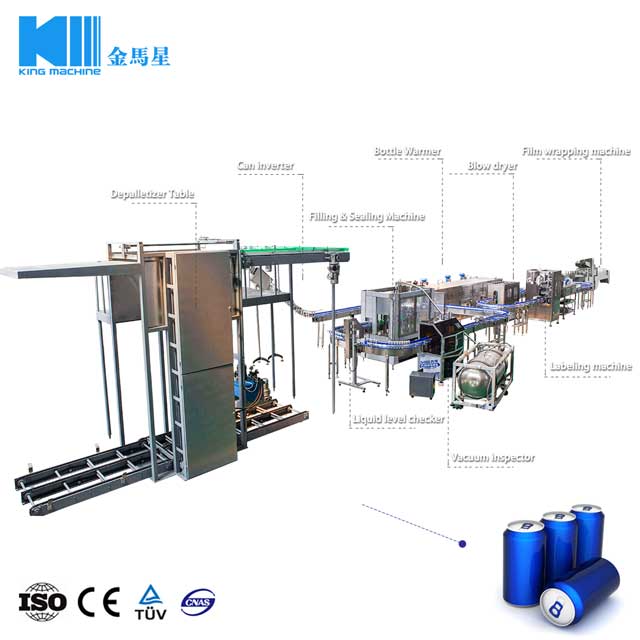

Use: For beverage production line

Principle:Inject liquid nitrogen into the tank,liquid nitrogen will gasify after capping. Nitrogen gas is equal to 700 times the volume of liquid nitrogen .This will add pressure to bottles and avoid the occurrence of plaque product bottle phenomenon.

Weight:160KG

Pulse injection modes can reduce pressure and the cost of liquid nitrogen, decrease operating costs.

Vacuum insulation - Low rate of evaporation

(NER)0.15L/H, liquid nitrogen machine can decrease operating costs.

Nozzle Blanketing canprevent outside air into spray chamber internal frost.

Liquid nitrogen level positioning control, Horizontal pressure stable, can improve the liquid nitrogen dose accuracy,

and at the same time reduce liquid nitrogen flash loss.

Liquid level by dynamic positioning control system, there will be no problem of the electronic level control system and electrically operated valve.

Liquid gas separator, to ensure the super cold of the liquid nitrogen, improve the quality of pure liquid, help to liquid nitrogen dose accurately.

Buffer nitrogen filled function, effectively prevent the liquid nitrogen rebound spill, liquid nitrogen pick up quantity is stable, also ensure that the tank pressure stable. Equipped with a filter 10um,to remove particle pollution.