© 2023 Zhangjiagang King Machine Co., Ltd. All rights reserved.Sitemap / Privacy Policy

- Home

- Products

- Solutions

- Why King Machine

- Resource

- Contact Us

- Blowing filling capping combiblock machine

- 330ml-1L Water filling line

- Can Juice filling line

- Glass bottle wine filling line

- 3-10L Water filling line

- PET juice filling line

- Oil filling line

- 5 gallons Water filling line

- Glass bottle juice filling line

- Rotary Jam Filling Line

- PET carbonated drink filling line

- Juice with pulp hot filling line

- Labeling machine

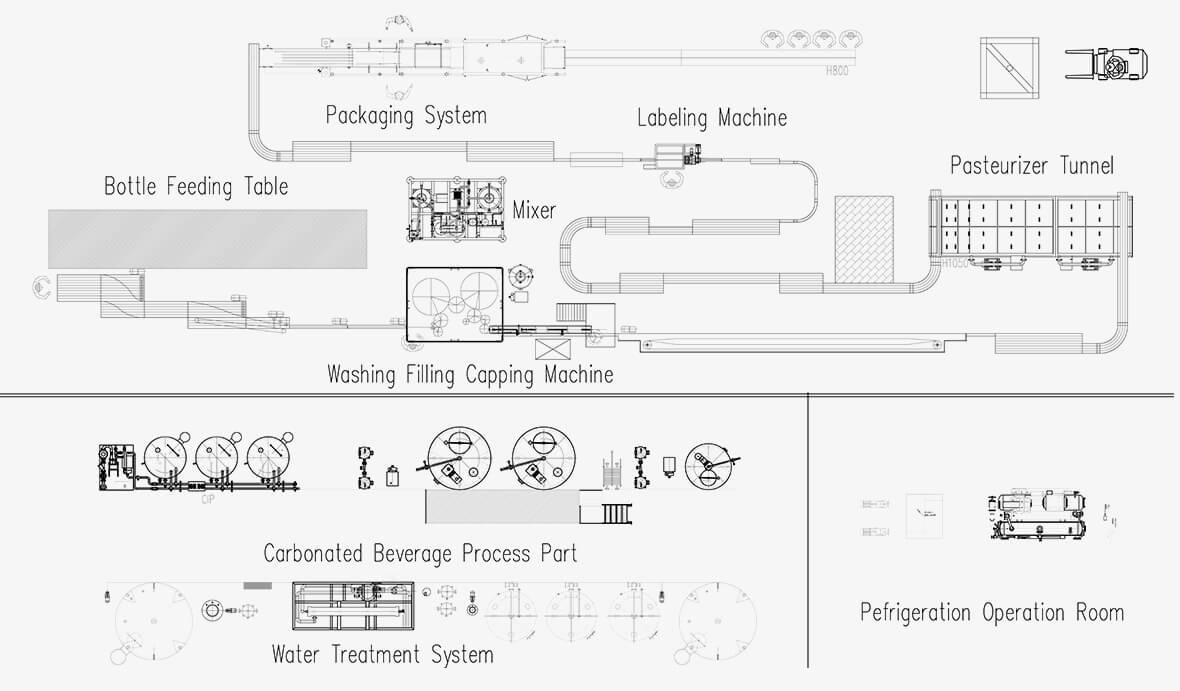

- Glass Bottle Beer Filling Line Solution

- Glass bottle juice with pulp hot filling line

- Packing machine

- Can carbonated drink filling line

- Daily chemical product filling line

Successful cases

Successful cases