© 2024 Zhangjiagang King Machine Co., Ltd. All rights reserved.Sitemap / Privacy Policy

Juice With Pulp Hot Filling Machine (Glass Bottles)

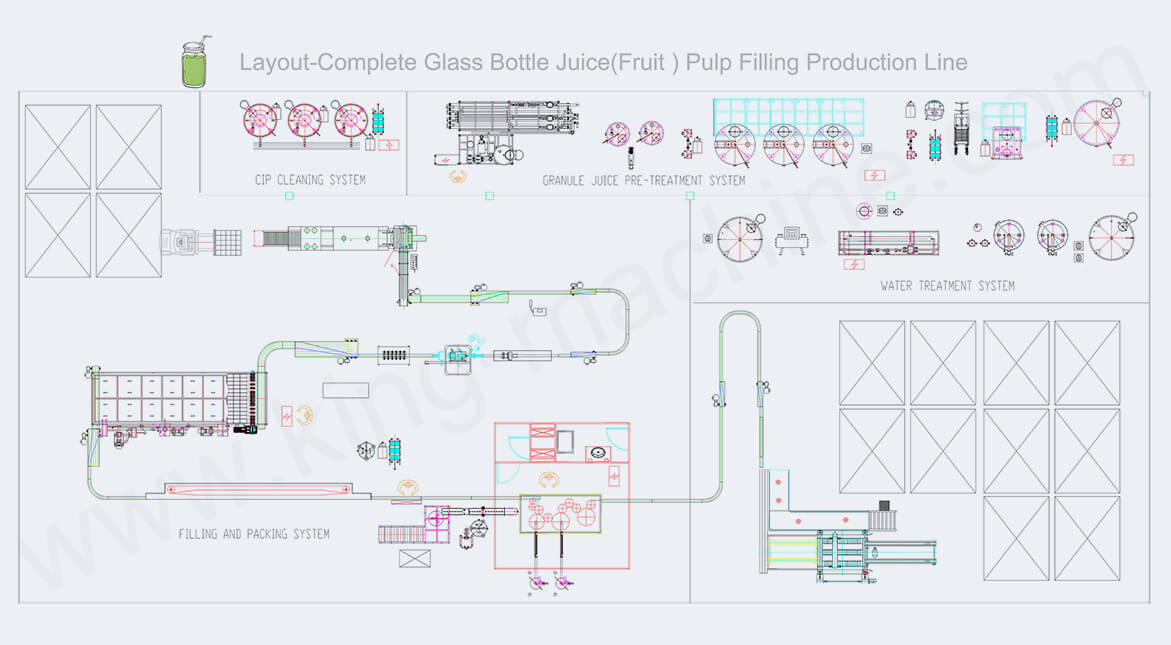

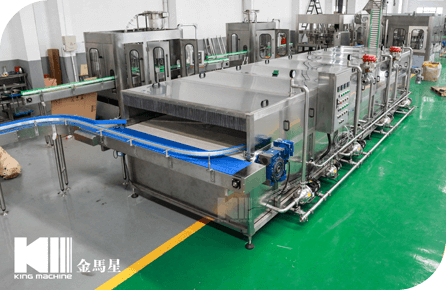

Monoblock Washing ,pulp filling, juice filling, capping 4 in 1 machine is mainly used in the juice with pulp hot filling operations. The four functions of bottle rinsing,pulp filling and juice filling and capping are composed in one body of the machine. The whole process is automatic.