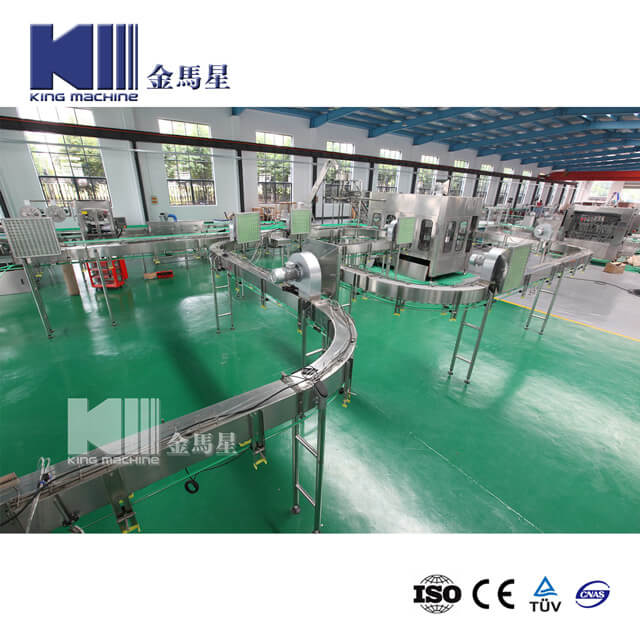

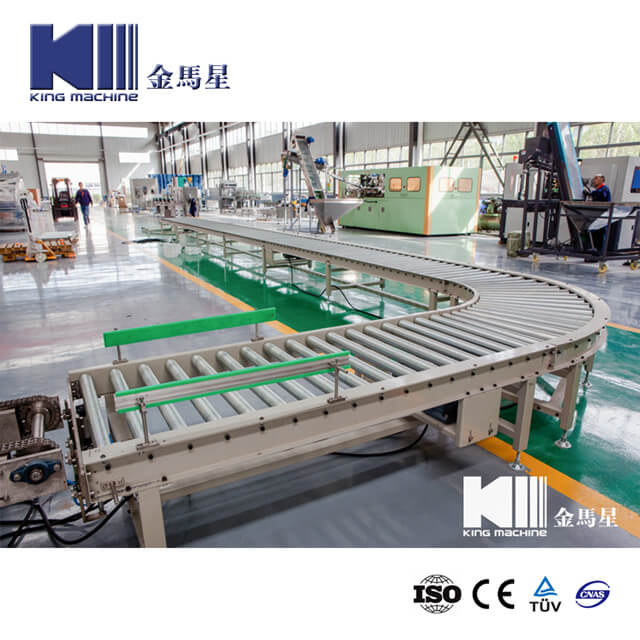

Automatic CIP system/CIP cleaning/CIP machine is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, alkali and hot water, in which temperature can be set up for acid, alkali and hot water.

Automatic CIP system/CIP cleaning/CIP machine is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, alkali and hot water, in which temperature can be set up for acid, alkali and hot water.

A new generation of touch screen operation, which is both open-and-shut and easy to handle.

Function:The CIP SYSTEM can cleaning equipments of blending system automatically, from start until to the end of cleaning Work, all jobs are done by the control system automatic performance which function had been set in advance, the operator only Makes the switching operation, all blending system equipment will be cleaned fast and simply.

CIP EQUIPENT

PLATE ECHANGE HEATER

1.Liquid store TANK

2.Acidity, alkalescent

3.Liquid PH &118alue

4.Mensuration machine

5.Acidity Liquid, alkalescent

6.Liquid Dose pump

7.CIP infeed PUMP

8.CIP Liquid reclaim pump

9.CIP infeed &reclaim piprline

10.Automatic pneumatic valve

CIP CLEANING PROCESS

CIP CLEANING PROCESS

1.Water wash (water wash leftover)

2.Lye wash (lye cycle)

Lotion:Lye, specialty clean lotion

Consistency:1~2%

Temperature:70~90 degree

3.Acidity Liquid wash

Lotion:Nitric acid, specialty clean lotion

Consistency:0.5~1.5%

Temperature:60~80 degree

4.Pasteurizer

Lotion:Water

Temperature:90~95 degree

CIP CLEANING CHARACTERSTICS

5.Before cleaning process, Setting target subject & checking, to avoid mistake of choosing

6.CIP Liquid store TANK automatic Liquid-level inspection and complementarily

7.Acidity Liquid, Lye automatic adding inspection

8 Heat up temperature and circumfluence temperature controller

9.All of automatic valve and pump start and stop controller

10.Running statues display

11.Failure automatic pause and warning

Q:How about the spare parts?

A:We will send one year enough easy broken spare parts together with the machines,shipping together.During the warranty time,we will supply the spare parts with our cost including the delivery fees.

Q:How long time for installation?

A:According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Q:How to install my machines when it arrives?how much the cost?

A:We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation and USD80/day/person.

Q:When can I get my machine after I paid?

A:Normally production time is around 30-60days,the exactly depend on what kind of machine you order.The shipping time is based on your destination port.

Q:What’s your guarantee or the warranty of the quality if we buy your machines?

A:We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q:Are you a trading company or a manufacturer?

A:We are an Original Equipment Manufacturer so that we can provide you high quality machines in raeasonable price, Welcome to visit us.

Automatic CIP system/CIP cleaning/CIP machine is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, alkali and hot water, in which temperature can be set up for acid, alkali and hot water.

Automatic CIP system/CIP cleaning/CIP machine is specially designed for the clean up of beverage production line and filling equipment, with three cleaning sections of Acid, alkali and hot water, in which temperature can be set up for acid, alkali and hot water. CIP CLEANING PROCESS

CIP CLEANING PROCESS