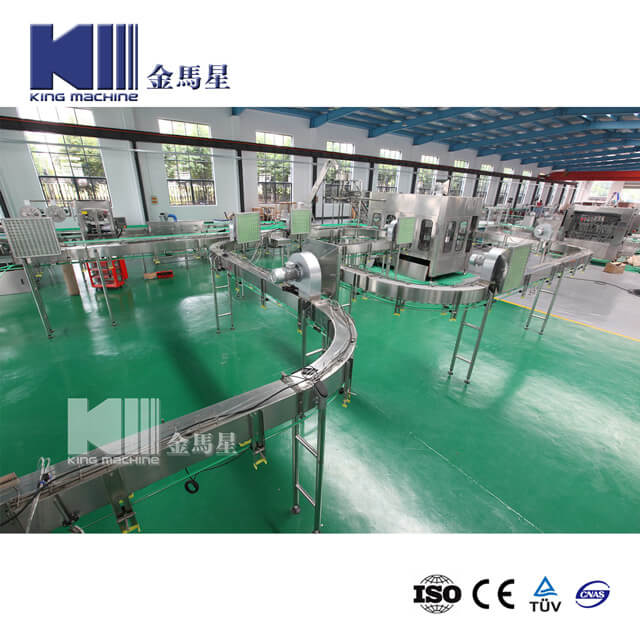

Final Products

KING MACHINE - Packaging Machinery Supplier - CE SGS BV TUV ISO9001

Product Description

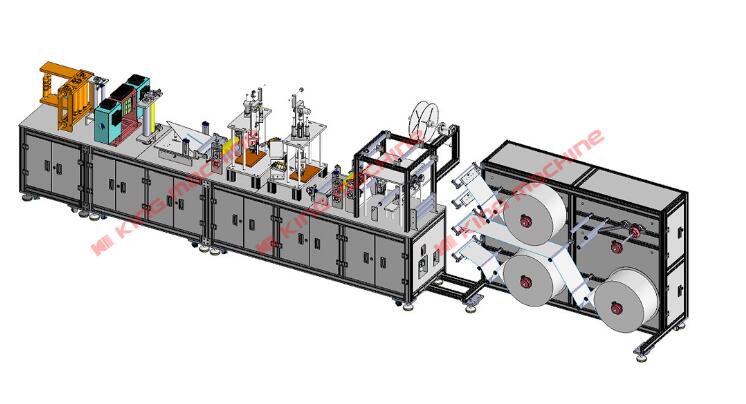

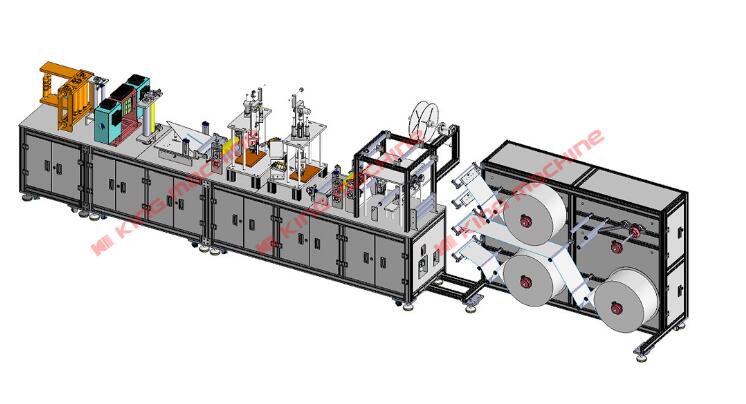

King Machine Non-woven Face Mask Making Machine.

*If there are special requirements for the customer's voltage and frequency, the project scheme equipment sha ll be re quoted according to the voltage and frequency requirements.

*If other packing forms are added, the technical data of relevant engineering data shall be provided, and the quotation of the supplementary modified part shall be determined separately by the technology.

*The project plan is based on the standard equipment configuration provided by the c ustomer project process, if

there are individual adjustments, or customer owned equipment, you need to communicate with us.

King Machine Face Mask ( cup type ) Making Machine.

The production line to achieve the N95 mask fully automated production, mainly including coil material, nasal string loading, ultrasonic

Wave pressure, earband material and welding, folding pressure, mask pre-cutting, finished material and other processes, complete from the raw materials to N95 mask finished production process. Our company's equipment can increase the machine vision automatic complement mask size, to ensure good rate. N95 mask with cup cavity, wear comfortable, no compression, mask filtration effect is good, suitable for a variety of face types, N95 mask on the aerodynamic diameter of the particles of more than 95, can effectively prevent airborne microbial infection. Can effectively protect the first-line health care workers, for the general user, the protection effect is far better than the ordinary flat-style mask.

King Machine Face Mask Making Machine Performance and Characteristics:

This machine produces non-woven face mask body automatically from raw material to finished mask body

1.Steel structure

2.High stability and output

3.Automatic tension control system

4.Adjustable ultrasonic unit

King Machine Face Mask Making Machine Performance and Characteristics:

5.Adjustable speed control system

6.Produce non woven face mask automatically from raw material to finished product.

7.Inserting nose wire,then forming,sealing and cutting finished mask blank.

8.The size of mask blank can adjust according to customers requirement. 9.With motor frequency adjustment panel and working button control.

Product Paramenters

| Dimension | 625 0mm L x 3500mm W x 1980mm H |

| Driving method | Servo motor and step motor |

| Electric control method | Computer PLC program control |

| Control panel | HMI (Touch Screen) and Button |

| Energy consumption | 380V 50/60HZ |

| Air pressure | 0.5 0.6Mpa |

| Applicable process | Double, three layers medical and common masks |

| Product specification | Standard 175 x 95mm S pecia l 180 x 95mm 145 x 90mm 125 x 90mm |

| Capacity | About 80 100 pc/ min |

| Qualification rate | Above 99% |

| Weight | About 800 kg |