News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Bottled water filling machinery and equipment need to be used for production for a long time. If there are always various problems that need to be repaired, or the operation is not smooth, it is very headache and thorny. The most important thing is the impact on production capacity, so choose a good equipment is very important. As a professional equipment supplier, here I will teach you how to choose good bottled water filling machine.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Bottled water filling machinery and equipment need to be used for production for a long time. If there are always various problems that need to be repaired, or the operation is not smooth, it is very headache and thorny. The most important thing is the impact on production capacity, so choose a good equipment is very important. As a professional equipment supplier, here I will teach you how to choose good bottled water filling machine.

How To Choose A Useful Bottled Water Filling Equipment

Views: 1359

Author: Site Editor

Publish Time: 2021-11-17

Origin: Site

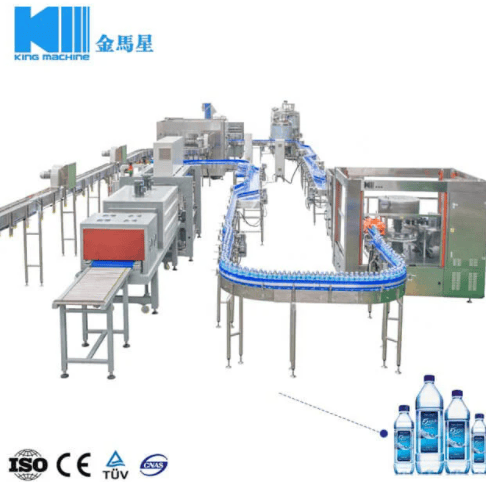

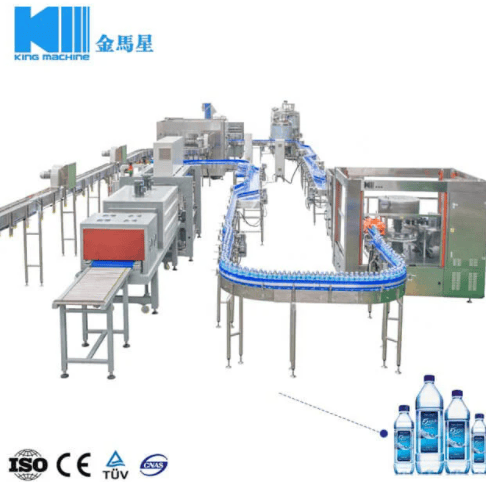

Bottled water filling machinery and equipment need to be used for production for a long time. If there are always various problems that need to be repaired, or the operation is not smooth, it is very headache and thorny. The most important thing is the impact on production capacity, so choose a good equipment is very important. As a professional equipment supplier, here I will teach you how to choose good bottled water filling machine.

Before choosing a bottled water filling machine, we must first understand the quality and flow rate of the raw water. Only in this way can the water treatment process and the output of the bottled water filling machine be determined. Don't just trust the photos and information on the internet, go to the manufacturer and have a comprehensive understanding of the equipment. Try to choose a production company rather than a trade company. The quality of production-oriented enterprises is more guaranteed, and the after-sales is more guaranteed. Strictly control prices, but cannot blindly pursue cheapness. Any industry has become transparent, and we should believe that you get what you pay for. We should spend a lot of money to do practical things according to our needs.

How can we better choose an easy-to-use bottled water filling equipment?

1. Look at the appearance of bottled water filling equipment

The aesthetics of the bottled water filling production line is that the benevolent sees the benevolent and the wise, but the appearance of any equipment must be based on the ease of operation and maintenance. If some accessories of little significance are added purely for aesthetics, it will inevitably lead to an increase in production costs. The customer must ultimately bear this cost.

2. Look at the material of bottled water filling equipment

At present, the material of bottled water filling production equipment on the market generally uses 304 stainless steel, but some manufacturers often choose 202 stainless steel in order to reduce the cost. Although there is no obvious difference in appearance, in the long run, the corrosion resistance and corrosion resistance of the equipment often have serious effects.

3. Look at the accessories of bottled water filling equipment

A good bottled water filling production equipment is not a stacking of accessories of well-known brands, but a system project with the same performance. High-quality accessories will naturally bring better performance and increase the purchase cost. The balance point inside requires detailed communication between the customer and the manufacturer, and the test is the manufacturer's engineering research and development capabilities, and it is impossible to repeat them one by one.

4. Look at the design of bottled water filling equipment

There is only one standard for the quality of the design, which is to reduce costs while facilitating operation and maintenance. If customers have special requirements, they also need to communicate with the manufacturer in detail.

The bottled water filling equipment production line is a complete set of production equipment for bottled, purified water, mineral water, mountain spring water, and mineral water. The entire production process includes bottle blowing, water purification, water disinfection, water filling, water packaging, and other parts. The blowing part is to blow the preform with a blow molding machine, first put the preform into the oven to preheat the preform, and then put the preheated preform into the blowing host for the next step to blow the bottle out of the mold. Shaped bottles, blown bottles are used for filling bottled water. This is a more comprehensive the design of bottled water filling line.

The above are the points summarized based on our many years of experience, I hope this can help you. For more information about our products, please do not hesitate to contact us.