News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

In this guide, we'll walk you through the essential considerations to help you select the perfect automatic water filling machine that meets your production requirements.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

In this guide, we'll walk you through the essential considerations to help you select the perfect automatic water filling machine that meets your production requirements.

How to Choose the Right Automatic Water Filling Machine for Your Production Needs

Views: 1478

Author: Site Editor

Publish Time: 2023-08-08

Origin: Site

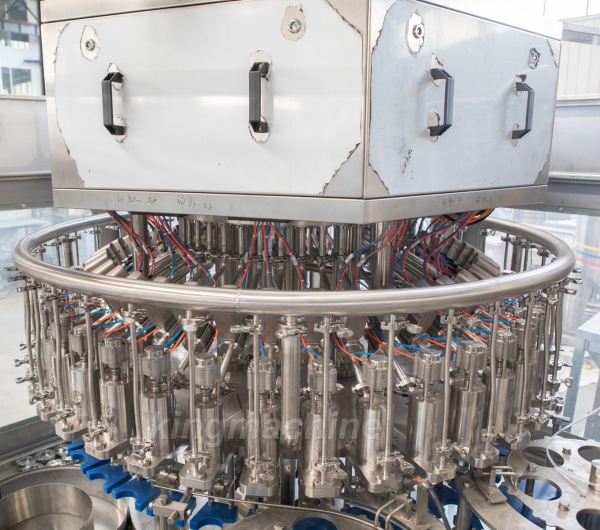

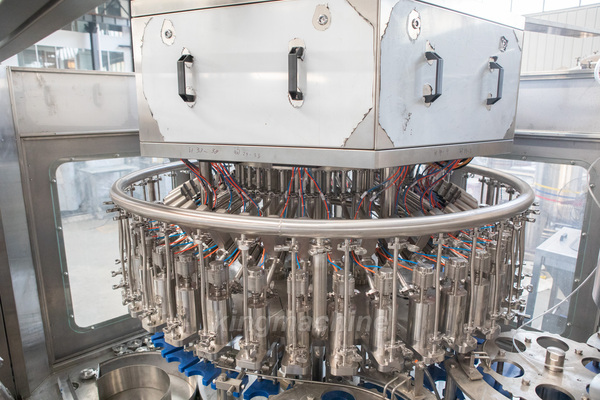

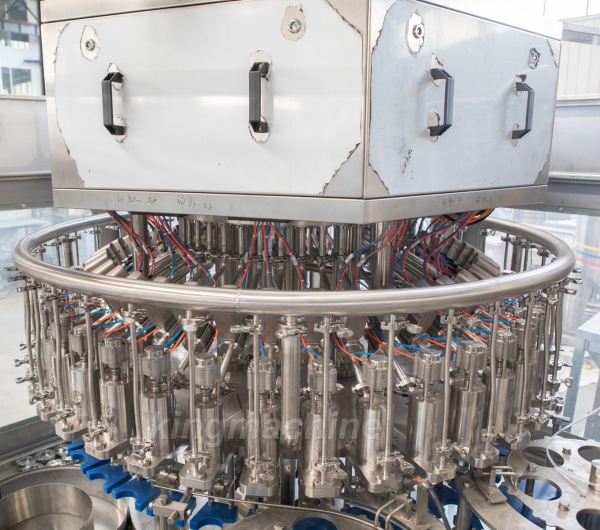

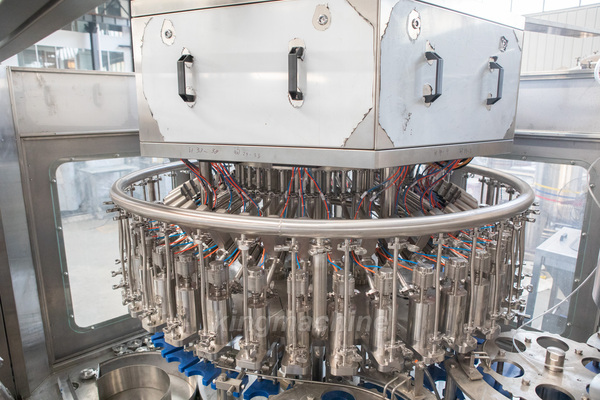

In today's fast-paced manufacturing landscape, choosing the right equipment is crucial to ensuring efficiency, quality, and success. Automatic water filling machines have become indispensable tools for various industries, streamlining the process of bottling liquids. In this guide, we'll walk you through the essential considerations to help you select the perfect automatic water filling machine that meets your production requirements.

Understanding Your Production Needs

Bottle Types and Sizes:

Begin by evaluating the types and sizes of bottles you'll be using. Different water filling machines are designed to handle specific bottle shapes and volumes, so it's essential to choose one that accommodates your product seamlessly.

Production Capacity:

Determine your desired production output. Automatic water filling machines come in a range of speeds, from slow to high-capacity models. Select a machine that aligns with your production goals and growth projections.

Filling Technology

Gravity Filling:

This method relies on gravity to fill bottles, making it suitable for non-carbonated liquids. It's a simple and cost-effective solution for products like still water and juices.

Pressure Filling:

Ideal for carbonated beverages, pressure filling ensures consistent carbonation levels by maintaining pressure during the filling process. Consider this option if you're bottling sparkling water or sodas.

Hygiene and Sanitization

CIP Systems:

Clean-In-Place systems are crucial for maintaining hygiene standards. Look for a water filling machine equipped with automated cleaning features that prevent cross-contamination and ensure product purity.

Ease of Use and Maintenance

User Interface:

An intuitive user interface simplifies machine operation and reduces the learning curve for your staff. Look for a machine with user-friendly controls and clear instructions.

Maintenance Requirements:

Choose a water filling machine with easily accessible components for cleaning and maintenance. Regular upkeep ensures consistent performance and prolongs the machine's lifespan.

Quality and Reliability

Build Materials:

Opt for a water filling machine constructed from high-quality, durable materials that can withstand the demands of continuous production.

Manufacturer Reputation:

Research the reputation of the manufacturer. Look for reviews, testimonials, and case studies to gauge the reliability and after-sales support of the company.

Considering King Machine

As you navigate the process of choosing the right automatic water filling machine, consider King Machine. With a reputation for excellence and innovation, King Machine offers a range of cutting-edge water filling solutions that cater to various production needs. Our commitment to quality, reliability, and customer satisfaction sets us apart in the industry.

In conclusion, selecting the right automatic water filling machine involves a comprehensive evaluation of your production requirements, filling technology, hygiene standards, ease of use, and overall quality. By making an informed choice, you're investing in the efficiency and success of your manufacturing process. Choose King Machine as your partner in achieving seamless and efficient water bottling operations.