News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

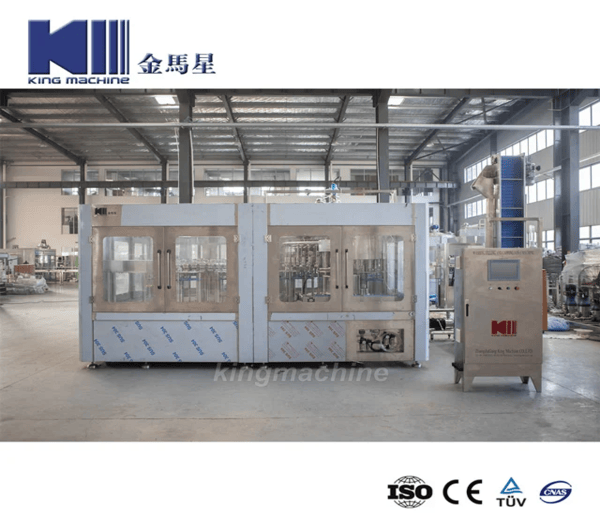

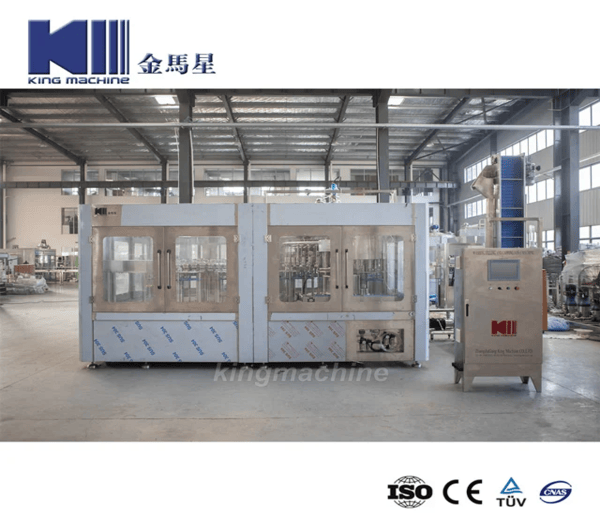

Here are the 7 main things you need to look for to select the best beverage filling machine.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Here are the 7 main things you need to look for to select the best beverage filling machine.

How to Select the Best Beverage Filling Machine

Views: 1403

Author: Site Editor

Publish Time: 2023-02-07

Origin: Site

Juice production, water filling, or beverage businesses need several machines but the most important one is the beverage filling machine. It brings several benefits due to automation, but to get all the benefits, it is essential to select the right machine.

Top 7 qualities to look for when selecting the best beverage filling machine.

Here are the 7 main things you need to look for to select the best beverage filling machine.

1. Filling rate

The first thing to look for is the filling rate. It depends solely on your business requirements and the viscosity of your product. On average, machines with 16 filling heads can fill around 120 bottles in a minute. However, with your specific requirements, you may get machines with higher or lower filling rates.

2. Beverage type

The next important thing to consider is your beverage type because different liquids have different qualities:

· Viscosity

· Having solid particles in them (fruit chunks)

· Carbonation

Every machine is made according to specific beverages, so when selecting one, you must ensure that it is compatible with your requirements.

3. Automation requirements

The next thing to look for is automation-level requirements. Some machines take care of everything in beverage filling factories. Similarly, some machines need humans to work on them. It depends on the complexity of your filling, production process, and hygiene standards.

On average, a filling machine may only need one person to work on the control panel because of its automation capabilities.

4. Scalability options

Next up is the scalability you get with your machinery. Growing businesses won't need machines that may need to scale up. However, it is a very important quality for small businesses because when they buy one machine that scales up at a very low cost, it is beneficial for those businesses in the long term.

5. Customization options

Just like scalability, you may also need some customization options for your machine. The most common example is changing container design, size, or height. So, if the beverage filling machine has a customizable filling head, you may adjust it according to the container. Most modern machines can do this with the click of a button.

6. The structural quality of the machine

Buying a beverage filling machine is a long-term investment, so you must look for good structural quality. Using high-gauge metal made with alloys like stainless steel ensures that your machine will last for years without any critical issues. However, to maintain the structural quality, you must get regular maintenance for your machine.

7. Hygiene standards and other ratings.

Lastly, you must look for any specific ratings for machinery according to the beverages. For instance, beverages containing alcohol need an ATEX rating for them. Additionally, keep an eye on the hygiene standards you must meet, as the machine must provide the same or better standards.

Here is the best range of beverage filling machines you need to check out.

Every beverage filling machine here comes with different qualities and features. So, for the best performance and experience, you must pick the right one with the required qualities as discussed above.