News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

In this article, we will compare water filling machines and manual filling processes to determine which is more cost-effective for your business.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

In this article, we will compare water filling machines and manual filling processes to determine which is more cost-effective for your business.

Water Filling Machines vs. Manual Filling: Which is More Cost-Effective?

Views: 1687

Author: Site Editor

Publish Time: 2023-09-15

Origin: Site

In the world of beverage production, the choice between water filling machines and manual filling methods can significantly impact a company's bottom line. Efficiency, accuracy, and overall costs are essential factors to consider. In this article, we will compare water filling machines and manual filling processes to determine which is more cost-effective for your business.

The Efficiency Factor

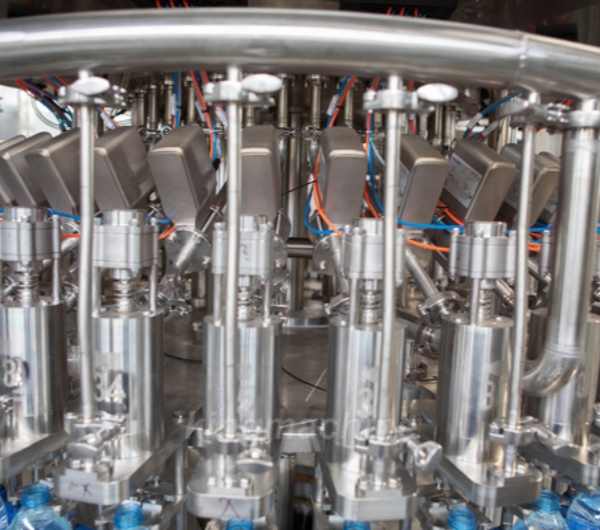

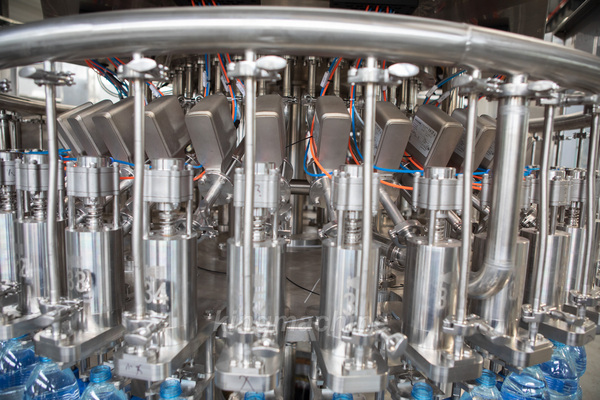

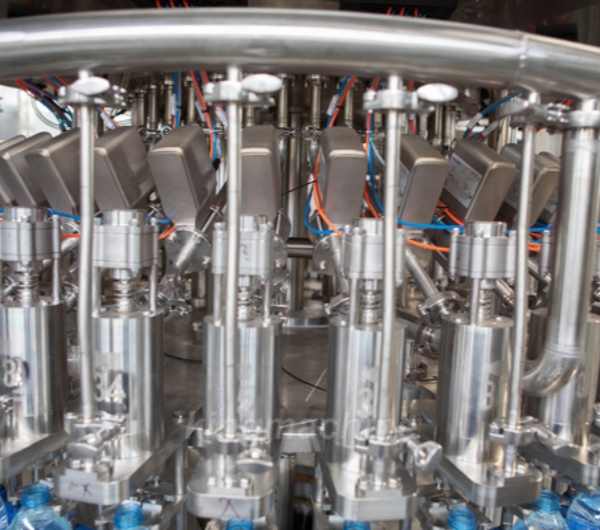

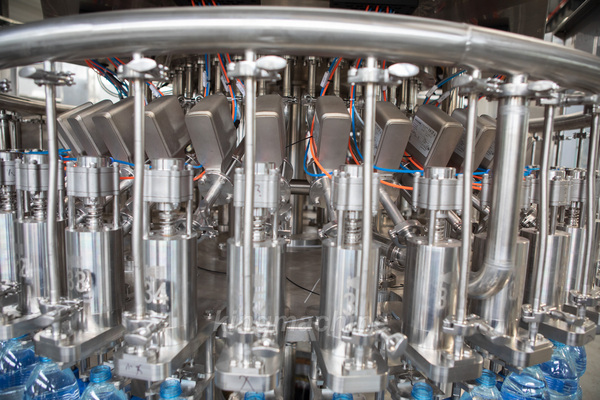

Water Filling Machines: Streamlined Production

Water filling machines are designed for efficiency. These automated systems can fill a large number of bottles quickly and consistently, minimizing human error and reducing labor costs. With their precision and speed, they can significantly increase production rates, making them ideal for high-volume operations.

Manual Filling: Labor-Intensive and Time-Consuming

Manual filling, on the other hand, is a labor-intensive process. It requires trained workers to fill each bottle individually, which can slow down production considerably. Not only is it time-consuming, but it also presents a higher risk of inconsistency in fill levels, potentially leading to product waste and quality issues.

Accuracy and Consistency

Water Filling Machines: Precision Matters

Water filling machines are known for their accuracy and consistency. They can dispense the exact amount of liquid into each bottle, ensuring uniform product quality. This level of precision is crucial, especially in industries where product consistency and compliance with regulations are paramount.

Manual Filling: Variability is a Challenge

Manual filling processes are prone to variability. Factors such as operator fatigue, inattention, or variations in bottle sizes can lead to inconsistent fill levels. This variability can result in product quality issues and potential customer dissatisfaction.

Cost Considerations

Water Filling Machines: Initial Investment, Long-Term Savings

While the initial investment in water filling machines can be substantial, they often lead to long-term savings. With increased production rates, reduced labor costs, and minimized product waste, these machines can pay for themselves over time.

Manual Filling: Lower Upfront Costs, Higher Operating Costs

Manual filling methods may have lower upfront costs, but they can incur higher operating costs due to labor expenses and potential product wastage. Over time, these expenses can add up, making manual filling less cost-effective in the long run.

Environmental Impact

Water Filling Machines: Eco-Friendly Solutions

Many water filling machines are designed with sustainability in mind. They can reduce plastic waste by filling bottles accurately and minimizing spillage. Additionally, their energy-efficient operation can contribute to a smaller carbon footprint.

Manual Filling: Potential for Waste

Manual filling processes are more susceptible to product wastage, leading to increased plastic waste and environmental impact.

The Clear Choice for Cost-Effective Filling

In the comparison between water filling machines and manual filling processes, the cost-effectiveness of water filling machines becomes evident. While the initial investment may be higher, their efficiency, accuracy, and long-term savings make them the more cost-effective choice for businesses, especially those with high production volumes.

At King Machine, we understand the importance of cost-effective solutions for your beverage production needs. Our water filling machines are designed to optimize your production process, ensuring efficiency, accuracy, and sustainability. Contact us today to explore our range of water filling solutions and elevate your production capabilities.

Choose King Machine for a cost-effective and efficient approach to water filling.