Blowing filling capping machines are revolutionizing manufacturing by delivering unmatched efficiency. These machines combine multiple processes into one seamless operation, saving you time and resources. Their integration with smart technologies, like IoT, enhances performance and minimizes downtime.

Key Takeaways

Blowing filling capping machines do many tasks at once. This saves time and cuts costs.

Automation reduces mistakes, makes products better, and keeps workers safer. This means fewer problems and recalls.

Using smart tech like IoT and AI helps work faster. It allows real-time checks and better planning.

These machines use less energy and create less waste. This saves money and helps the environment.

Buying these machines can make more products quickly. It also keeps customers happy with good quality.

Automation: The Key to Efficiency

Reducing Human Error

Automation plays a vital role in minimizing human error in manufacturing. Machines operate with precision, ensuring tasks are completed accurately every time. For example:

Automated systems reduce errors in data entry by maintaining high accuracy and consistency.

They identify and flag incorrect data, improving overall quality.

Robots and computer systems enhance production speed and precision, leading to fewer defects.

Automation also improves workplace safety by handling dangerous tasks, protecting workers from harm.

By integrating automation into your processes, you can achieve higher product quality and fewer costly recalls. This is especially true for blowing filling machines, where precision is critical to maintaining product integrity.

Accelerating Production Speeds

Automation significantly boosts production speeds by streamlining repetitive tasks and optimizing workflows. Many companies have already experienced these benefits.

Ensuring Consistency in Operations

Consistency is essential for maintaining product quality and meeting customer expectations. Automated systems excel at delivering uniform results. Unlike manual processes, machines do not tire or lose focus. They perform the same task repeatedly with identical precision. This ensures that every product meets the same high standards. In industries using blowing filling machines, this consistency is crucial for maintaining brand reputation and customer satisfaction.

Automation also reduces variability in production, making it easier to predict outcomes and plan for future growth. By relying on automated systems, you can ensure your operations remain steady and reliable, even during high-demand periods.

Blowing Filling Integration: Streamlining Production

Combining Processes in One Machine

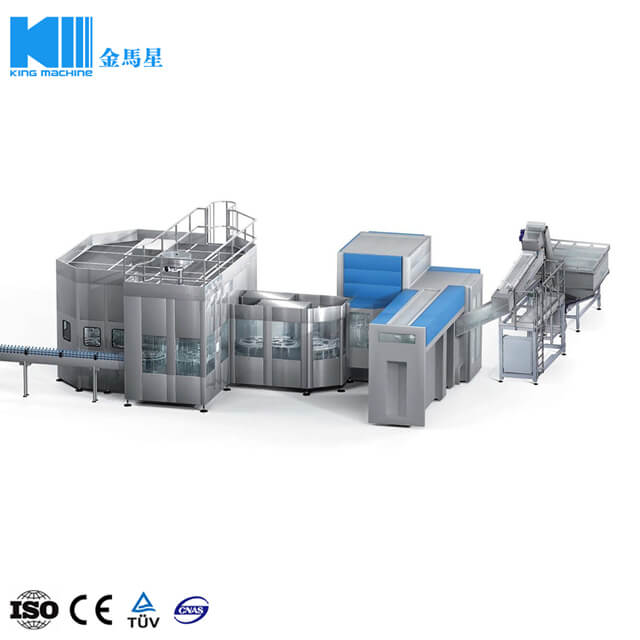

Integrating blowing and filling processes into a single machine simplifies production. This combination eliminates the need for separate equipment, reducing complexity in your operations. You can achieve higher sterility and efficiency. This integration also lowers your upfront investment. By using one machine instead of multiple, you reduce equipment costs and per-unit manufacturing expenses. The compact design ensures efficient space utilization, making it ideal for facilities with limited room.

Reducing Downtime and Maintenance

When you combine blowing, filling, and capping processes, you reduce downtime significantly. Fewer machines mean fewer breakdowns and less maintenance. For instance, King Machine’s Blowing-Filling-Capping Combiblock Machine improves production line efficiency by 25%. It also decreases maintenance costs by up to 50%.

Streamlined operations also minimize manual handling, which reduces wear and tear on equipment. This leads to lower energy consumption and fewer interruptions in production. With these benefits, you can maintain a steady workflow and meet your production goals more effectively.

Saving Space and Costs

Space and cost savings are major advantages of integrating processes. A single machine takes up less floor space, allowing you to optimize your facility layout. King Machine’s Combiblock Machine, for example, reduces floor space requirements by 35%. This compact design not only saves space but also cuts equipment investment by 20%.

By lowering energy consumption by 30%, these machines further reduce operational costs. You can allocate these savings to other areas of your business, such as innovation or marketing. This makes blowing filling machines a smart investment for long-term growth.

Advanced Technology in Blowing Filling Machines

Sensors and IoT for Real-Time Monitoring

Sensors and IoT technology are transforming blowing filling machines by enabling real-time monitoring and data analytics. These advancements allow you to track every stage of the production process with precision. For example:

IoT integration provides predictive maintenance, reducing unexpected breakdowns. This can boost production efficiency by up to 30%.

Sensors detect anomalies instantly, ensuring consistent product quality.

Data analytics from IoT systems help you optimize workflows and identify areas for improvement.

These features not only enhance operational efficiency but also minimize downtime. By adopting IoT-enabled systems, you can maintain a smooth production flow and achieve higher output with fewer interruptions.

AI-Driven Optimization

Artificial intelligence plays a crucial role in optimizing the performance of blowing filling machines. AI systems analyze data to ensure maximum output and minimal waste. They adjust fill levels with precision, reducing product loss and improving quality. This leads to higher customer satisfaction.

AI also minimizes downtime by predicting maintenance needs and automating complex tasks. For instance, robots powered by AI can handle bottles of various shapes and sizes with ease. This adaptability increases productivity and ensures your operations remain versatile. By leveraging AI-driven optimization, you can achieve faster production cycles and better resource utilization.

Precision Engineering for Accuracy

Precision engineering ensures that blowing filling machines deliver accurate and reliable results. Every component is designed to perform its function with exactness. This level of accuracy is essential for maintaining product consistency and meeting industry standards.

Advanced robotics further enhance precision by performing tasks like bottle handling and capping with minimal error. These systems adapt to different production requirements, making them suitable for a wide range of applications. With precision engineering, you can produce high-quality products while reducing defects and waste.

Energy and Resource Efficiency

Minimizing Waste in Production

Blowing filling machines help you minimize waste during production. These machines operate with precision, ensuring that every drop of liquid and every piece of material is used efficiently. By reducing errors and overproduction, you can save resources and cut costs.

Lowering Energy Consumption

Energy efficiency is another key advantage of blowing filling machines. These machines use advanced technology to optimize energy usage during production. By integrating multiple processes into one system, you can reduce the energy required to operate separate machines. This streamlined approach lowers your overall energy consumption.

Modern machines also come equipped with energy-saving features, such as variable speed motors and intelligent controls. These features adjust energy usage based on production needs, ensuring no energy is wasted. Lower energy consumption means reduced utility bills and a smaller carbon footprint for your business.

Supporting Sustainable Manufacturing

Blowing filling machines play a vital role in sustainable manufacturing. They streamline production processes, reducing labor costs and production times. By using lightweight materials and optimizing packaging designs, these machines help you minimize the use of plastic. Many models also support biodegradable packaging, aligning with consumer demand for eco-friendly products.

Regulatory pressures and shifting consumer preferences are driving the adoption of greener technologies. Blowing filling machines allow you to stay ahead of these trends. They can handle refillable and reusable packaging systems efficiently, helping you meet environmental standards while satisfying customer expectations. By investing in these machines, you can position your business as a leader in sustainability.

Blowing filling capping machines have become essential tools for modern manufacturing. Their efficiency comes from automation, process integration, and advanced technology. These machines help you reduce costs and increase output. You can also adapt to market demands, like switching to biodegradable bottles during a surge in eco-friendly packaging. Investing in these machines ensures you stay competitive while delivering superior quality products.