News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Are you thinking of how to double your productivity at low operation costs and labour? There is a well-designed automatic machine that can do this task with ease for you.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Are you thinking of how to double your productivity at low operation costs and labour? There is a well-designed automatic machine that can do this task with ease for you.

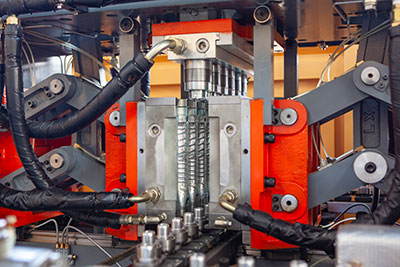

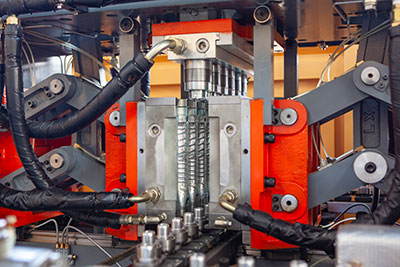

Why You Need Automatic PET Bottle Blowing Machine

Views: 1453

Author: Site Editor

Publish Time: 2020-12-17

Origin: Site

Are you thinking of how to double your productivity at low operation costs and labour? There is a well-designed automatic machine that can do this task with ease for you.

Automatic PET bottle blowing machine is a well-design machine that can process both Pet bottles and cans with high precision, speed, stability, and suitable for different bottle sizes.

Purchasing a quality automatic PET bottle blowing machine from a reliable and dependable manufacturer is a sure way to get the best experience. Moreover, you are certain to get the needed supports at any time.

Read on as we take you through the important things you need to know about this machine.

Special Features Of This Machine

The following features make this machine suitable for high standard full automatic process in the beverage production line.

1. System with Automatic Preform Unscrambler

The machine is designed with a new preform unscrambler that makes the system work efficiently. There is stability of the system without any hindrance during operation.

2. Unidirectional Preform Feeding Structure

This well-designed machine adopts a structure that takes care of block problem through unidirectional preform feeding. Moreover, the problem of abrasion is also solved. The structure of servo motor takes care of preform-separating during the operation.

3. Photoelectric Sensors

To make the task very easy, the machine has two photoelectric sensors. The sensors control preform-loading motor and preform-separating cylinder that notifies the worker to add more preforms into the machine’s hopper.

This prevents the machine from stopping when there is no enough preform in it during operation.

4. Heating System

The new heating system in the machine has a perfect design that decreases power consumption. The special oven is energy efficient and easy to maintain. There is cycle air-cooling system that keeps the oven at constant temperature.

5. Servo System on Main Transmission

There is use of servo arrangement on the main transmission which helps the system to work faster and steadily with high accuracy. There is no obstruction when the machine is in operation because of the design system.

6. The Stretching And Clamping System

The machine adopts innovative technology on the stretching and clamping system. The servo motor drives the two cranks to control the clamping system. This shortens the mold-clamping time. The servo motor that controls the stretching ensures stable bottle quality and high speed of bottle blowing.

7. Changing of Bottle Shape

The mold of the machine is drawer type which is easy for the change of mold. This makes work faster because within an hour, it can change a mold on the state of the same diameter of bottleneck.

8. Integration of Human-machine boundary

The integration of human-machine boundary enables live manufacturing information monitoring, daily auto record of production data, monitoring of the system, troubleshooting and failure warning.

9. Output

The output blower is from 2 to 10. The cavities are from 2,400 to 12,000 bottles per hour on 1.5 litres with water bottles.

Investing in a quality machine from a reliable and experienced manufacturer is essential. We manufacture quality products that work excellently and easy to maintain.

Kindly contact King Machine for your machine. We have the best team that will provide all the supports you need for high productivity. Try us today and you will be happy you did.