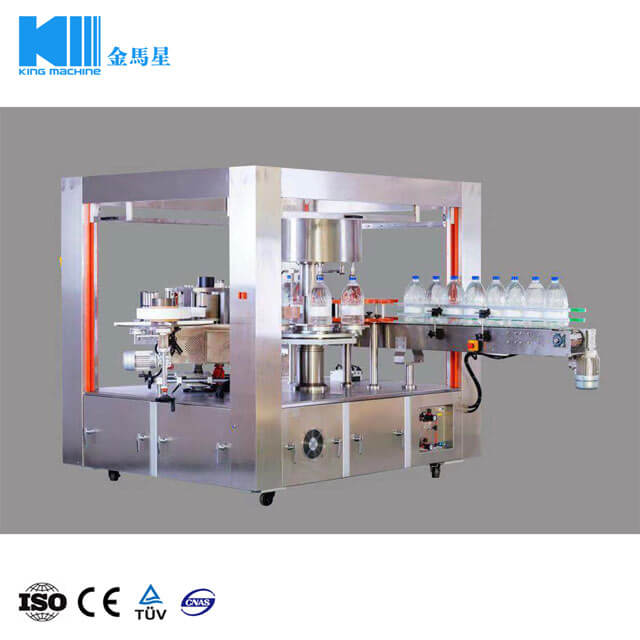

Adhesive Stick labeling machine for Top is special for stick the label on the top of cap

1.Effect: improve labeling efficiency, accuracy and quality and stability; Avoid many problems such as low efficiency of labor labeling, skew labeling, bubble, wrinkle, irregular labeling etc; Lower product cost effectively and make the product more beautiful which lead the product to be more competitive.

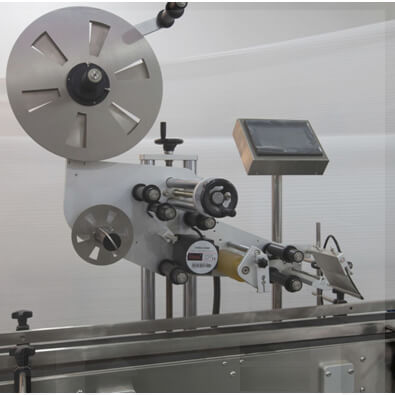

2.Adopt standard PLC+ touch screen+ stepper motor+ standard sensor electric control system. High safety coefficient; Complete English writing human-machine interface; has advanced fault remind function and operation teaching function; convenient to use and easy to maintain.

3.The clever design which allow user to mechanically adjust some structure combination and label winding, makes it easy to adjust the labeling position freely (it can be fixed easily after adjustment). All these make the change of different products and winding of labels more simple and saving time.

4.Adopt product guide gap elimination structure and label anti-deviation structure. The precision of labeling location achieves ±1mm;

5.Has the automatic detecting function to stop labeling if there is no bottle and automatic correcting function if there is no label. It solves the miss labeling problem caused by label roll.

6.Has fault alarm function, production counting function, energy saving function (the machine will be on standby mode when there is no label pass in the certain time), and production amount remind function; Parameter-set protection function;

Option: 1. hot printer/ code machine 2. Automatic feeding function(according to product) 3. Automatic feeding function (according to product) 4. Add labeling position 5. Other function (as customer’s requirement).

Adhesive Stick labeling machine for Top |

|  Adhesive Stick labeling machine for Top |

|  Adhesive Stick labeling machine for Top |

| Labeling precision | ±1mm (exclude the product and label deviation) |

| Labeling speed | 600-1200BPH (related to product size) |

| Product size applicable | 15≤width≤150mm, length≥10mm |

| Label size applicable | 15≤width≤150mm, length≥10mm |

| Size of whole machine | 1600×800×1400mm (length×width×height) |

| Power supply | 110/220V 50/60HZ |

| Weight | 180kg |

Main electrical parts configuration:

| Item | Brand |

| PLC | JANPAN,MITSUBISHI |

| Touch screen | TAIWAN,EVEIW |

| Labeling motor | GERMAN,KINCO |

| Labeling motor drive | GERMAN,KINCO |

| Labeling sensor | JAPAN,PANASONIC |

| Product sensor | JAPAN,PANASONIC |

| Conveyor motor | TAIWAN,HAITEC |

| Frequency converter | TAIWAN,SANCH |

Q:How about the spare parts?

Q:How about the spare parts?

A:We will send one year enough easy broken spare parts together with the machines,shipping together.During the warranty time,we will supply the spare parts with our cost including the delivery fees.

Q:How long time for installation?

A:According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Q:How to install my machines when it arrives?how much the cost?

A:We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation and USD80/day/person.

Q:When can I get my machine after I paid?

A:Normally production time is around 30-60days,the exactly depend on what kind of machine you order.The shipping time is based on your destination port.

Q:What’s your guarantee or the warranty of the quality if we buy your machines?

A:We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q:Are you a trading company or a manufacturer?

A:We are an Original Equipment Manufacturer so that we can provide you high quality machines in reasonable price, Welcome to visit us.

Q:How about the spare parts?

Q:How about the spare parts?