Outline

Prominent CONCEPT c series solenoid metering pump is controlled by a microprocessor variable stroke length and frequency of electromagnetic driven diaphragm metering pumps are used to measure a variety of liquid transportation

Works

Electromagnetic force driving rod driven reciprocating diaphragm in the head caused by head bore cavity volume and pressure changes

Changes in pressure caused by the suction valve and discharge valve automatically opens and closes to achieve quantitative chemical suction and discharge.

CONCEPT c series solenoid driven diaphragm metering pump rated capacity in the 0.7-23L / h range corresponding to the maximum output pressure of 16-1.5 bar displacement pump outlet can be adjusted stroke frequency selector switch buttons and LED light in accordance with the stroke length adjustment diodes indicate various operating status and alarm

(Working Conditions:Ambient Temperature:-10℃~+45℃)

Material: PP Or PVDF

Technical Parameters

3.1 General parameters

Repeat measurement accuracy of -5 +15%

Repeatability 2% over the operating range

Permissible ambient temperature -10 +45

Power supply 230V 50/60Hz -10% +6%

115V 50/60Hz -10% +6%

Input Power

Stroke frequency input power

90 strokes / min 12W

120 strokes / min 16W

180 strokes / min 24W

Protection class IP65

Insulation class F

Optional external contact control pulse signal passive contact

20ms pulse

Contact load 5V 0.5mA

External analog control optional 4-20mA current signal

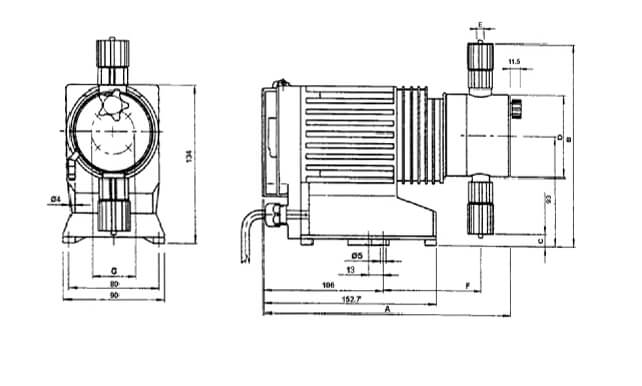

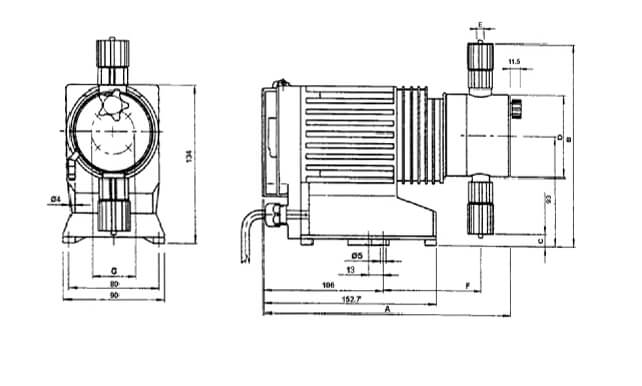

Mounting Dimensions:

Safety Precautions

Ø Prominent Prominent metering pump must not be used without testing or otherwise, and therefore recommended parts assembly

Consequences of personal injury and machine damage caused by the user conceit

Ø metering pump installation site to facilitate the operation and maintenance personnel access to the work area do not have any prejudice

Obstructions operation

Ø If the measured medium is dangerous or unknown operator liquid metering pump operation and maintenance to take

Safety glasses and gloves

Ø If the measured medium is liquid hazardous or unknown liquids before servicing To view performance parameters measured

Table emptying and cleaning inside the pump head

Ø Since testing at the factory may have residual water if the media can not be measured at the beginning to make contact with water

The water must be removed so that the pump can be turned by 180 degrees to release the water in the pump head and then use the appropriate referrals

Rinse the pump head from above internal quality through the suction port

Ø Maintenance metering pump discharge pipe pressure to give the first flush of the pump head cavity emissions and prohibit the use of

On the head with corrosive liquid rinse

If you turn back pressure metering pump shut-off valve can be generated when running the drain terminal Ø metering pump equipped with shut-off valve

Could be three times the maximum allowable back pressure which may cause rupture of the discharge line to prevent this

Occurrence suggested the use of a pressure relief valve to limit the maximum allowable value equipment within

Ø stroke length should be set in the work process metering pumps

Ø Use only the hose diameter corresponding to the snap ring hose connectors and hose specifications required otherwise no

Act to ensure the stability and lasting connections do not reduce the size of the hose lines longer or medium viscous To

Use larger cross-section of the pipeline and pulsation dampeners

Dangerous electrical repairs must be carried out by a qualified electrician

Dangerous to take off before servicing the power plug or off

Open relays should disconnect its power supply if

To ensure that the repair process pump power will not be turned