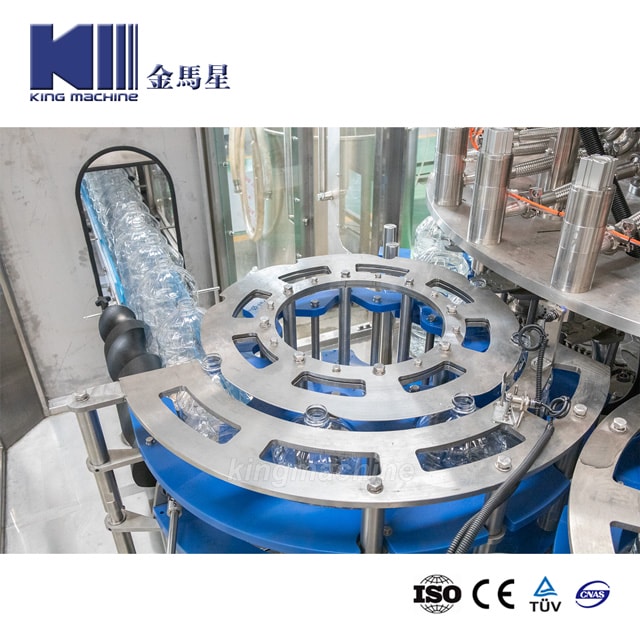

| NO. | Items | Specification |

| 1 | Model : | 24 filling heads and 8 capping heads |

| 2 | Capacity : | 6000 B/H for 1L |

| 3 | Filling precision : | ±4g |

| 4 | Pressure of washing : | 0.2 Mpa |

| 5 | Compressed air consumption : | 600L /Min |

| 6 | Power of main motor : | 5 Kw |

| 7 | Dimension: | 3150 * 2500 * 2300 MM |

| 8 | Weight : | 3500 Kg |

This machine is

a new generation of filling and capping integrated machine, using

Toledo load cell. No bottle, no filling, no capping, reducing loss;

continuous filling and capping, high output, no material splashing;

twists, star wheel, etc. are all fast-loading designs, easy to change

specifications, short time consuming, and high efficiency (replacement

Specifications one-key adjustment of the lifting height).