When it comes to beverage packaging, can filling is one of the most popular methods. However, the process of filling cans varies significantly depending on the type of beverage being packaged. Two of the most common beverage categories—carbonated drinks and juices—require distinct filling processes. In this article, we will explore the key differences between carbonated and juice can filling, discussing their respective processes, challenges, and equipment requirements.

Key Differences Between Carbonated and Juice Can Filling

The fundamental distinction between carbonated and juice can filling lies in the nature of the products themselves. Carbonated drinks, such as soda or sparkling water, are pressurized with carbon dioxide (CO2), which adds both complexity and challenges to the filling process. Juices, on the other hand, are non-carbonated and often include additional ingredients like pulp, vitamins, or flavorings, which must be carefully preserved throughout the filling process. These differences influence every aspect of the filling method.

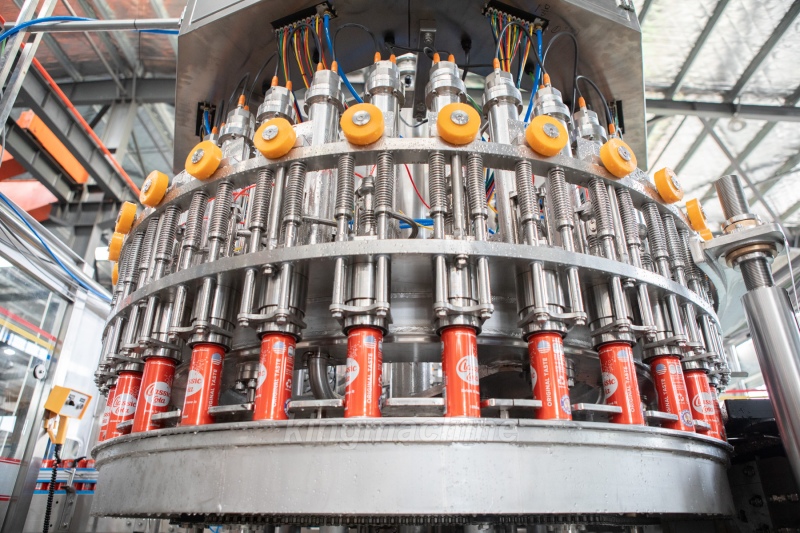

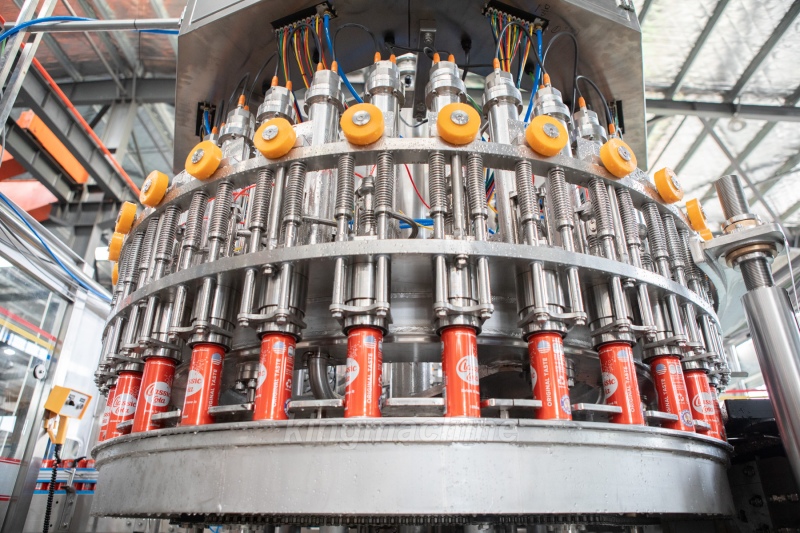

Carbonated Can Filling Process

The filling process for carbonated beverages requires special attention due to the carbonation itself. The CO2 in the drink creates pressure inside the can, which must be maintained to preserve the fizziness that consumers expect.

Filling Under Pressure

Carbonated drinks are filled under pressure to prevent CO2 from escaping. This pressurization ensures that the product maintains its carbonation through the packaging process, preserving its quality.

Filling Equipment

Specialized equipment is used to maintain the internal pressure of the product and ensure that it fills the cans without excessive foaming. Filling machines for carbonated beverages are designed to accommodate this pressure and control the fill volume precisely.

Foaming Control

One of the biggest challenges in carbonated can filling is controlling foam formation. Excessive foam can lead to product loss, as foam overflow during filling results in waste. To combat this, modern machines are designed to minimize foam production, often through careful control of the temperature and speed of filling.

Sealing Process

After filling, cans must be sealed immediately to prevent CO2 from escaping. This is why carbonated beverage fillers work in sync with high-speed can seamers to ensure the product is securely sealed before any gas escapes.

Juice Can Filling Process

The juice can filling process is quite different, primarily because it doesn’t involve carbonation. However, juices have their own set of challenges, particularly when it comes to preserving the product’s freshness and nutritional value.

Aseptic Filling vs. Hot Filling

Juice filling is typically done using either aseptic filling or hot filling methods. In aseptic filling, the juice and the packaging are sterilized separately before being filled in a sterile environment to prevent contamination. In hot filling, the juice is heated to a high temperature to kill bacteria before being filled into cans, which helps preserve shelf life without needing preservatives.

Handling Sensitive Ingredients

Juices often contain sensitive ingredients like pulp, vitamins, and minerals, which are prone to spoilage or degradation if exposed to air or contaminants. Therefore, filling must occur in a controlled environment to avoid compromising the product’s quality.

Filling Equipment for Juice

Juice filling machines are designed to handle products with different viscosities. Juices with pulp, for example, require special equipment to ensure the pulp is evenly distributed and doesn’t clog the filling system. Temperature control is also essential to maintain product quality, especially during hot filling.

Sealing Considerations

While sealing juice cans, the process is less about pressure and more about ensuring that the heat or aseptic environment is maintained to keep the product sterile and safe for consumption.

Challenges in Carbonated Can Filling

Pressure and Foaming Issues

Maintaining the right pressure is crucial for carbonated beverages, as failure to do so can lead to loss of carbonation, affecting the product’s quality. Managing foam is another critical challenge, as too much foam leads to product wastage.

Product Loss

Improper foam control can result in significant product loss, making it essential for manufacturers to use equipment designed to minimize this issue. Temperature, fill speed, and can positioning all play a role in reducing foam.

Maintaining Carbonation

Ensuring that carbonation levels remain consistent across batches is another significant challenge. Any lapse in pressure control can lead to inconsistencies, which is why carbonated drink fillers need precise monitoring systems.

Challenges in Juice Can Filling

Heat Treatment and Nutrient Retention

Heat treatment, especially in hot filling, is necessary for preventing bacterial growth but can degrade vitamins and affect the flavor of the juice. The challenge lies in finding the right balance between sterilization and preserving the nutritional value and taste of the product.

Contamination Risks

In aseptic filling, the biggest challenge is ensuring a completely sterile environment. Even a small lapse in sterilization can lead to contamination, affecting the entire batch. Stringent hygiene standards are essential in juice filling facilities.

Handling Pulp and Particulate Matter

Juices with pulp or other solids pose an additional challenge, as they require machines that can handle thicker liquids without clogging. These machines must also ensure that the pulp is evenly distributed in each can, preventing sedimentation.

Equipment and Technology Differences

Carbonated beverage fillers must maintain a pressurized environment throughout the filling process to retain CO2. These machines are equipped with foam-control mechanisms and are capable of filling cans at high speeds to minimize product loss and preserve carbonation.

Juice filling machines, on the other hand, focus on heat sterilization, viscosity handling, and maintaining an aseptic environment. They are designed to handle liquids of varying thickness, and in the case of juices with pulp, ensure that solids are properly managed.

Cost Considerations

Carbonated Filling

Carbonated filling tends to be more expensive due to the need for pressurized equipment and the challenges associated with maintaining carbonation. Specialized machines and rigorous quality control measures increase operational costs.

Juice Filling

Juice filling, particularly aseptic and hot filling, also comes with its own costs, especially in maintaining sterile environments and heat treatment processes. However, it may be less expensive than carbonated filling due to fewer pressure-related challenges.

Environmental Impact and Packaging

Both carbonated and juice can filling have environmental implications, particularly in terms of energy use and packaging waste. Carbonated can filling requires more energy to handle pressurization and CO2, while juice filling consumes energy through heating processes like pasteurization. However, both processes are increasingly adopting eco-friendly packaging and production practices to minimize their environmental footprint.

Conclusion

Both carbonated and juice can filling processes come with their own unique challenges and technical requirements. Carbonated filling must deal with the complexities of maintaining carbonation and controlling foam, while juice filling focuses on sterilization and preserving product quality. The choice of filling process depends on the type of beverage being packaged and the specific challenges involved, but with the right equipment and expertise, manufacturers can efficiently produce high-quality canned beverages in both categories.