Flow meter filling machines have become a vital tool in the packaging industry, providing precise measurement and control for a wide variety of liquids. These machines are versatile, accurate, and can handle different liquid viscosities, making them ideal for numerous industries. In this article, we’ll explore the types of liquids that benefit from flow meter filling machines and why they are the best choice for these products.

How Flow Meter Filling Machines Work

Flow meter filling machines operate by measuring the exact volume or mass of liquid passing through the system. Using advanced flow meter technology, these machines ensure consistent and accurate fills, whether for high-speed production lines or small-batch operations.

There are several types of flow meters used in filling machines, each suited to different liquid types:

Magnetic Flow Meters: Ideal for conductive liquids like water-based products.

Mass Flow Meters: Excellent for precise measurement of liquids based on mass, commonly used for high-viscosity or high-value liquids.

Volumetric Flow Meters: Used for measuring the volume of liquids, suitable for various applications.

This level of precision makes flow meter filling machines indispensable for products where accurate dosage or volume is essential.

Key Liquids That Benefit from Flow Meter Filling Machines

1. Water-Based Liquids

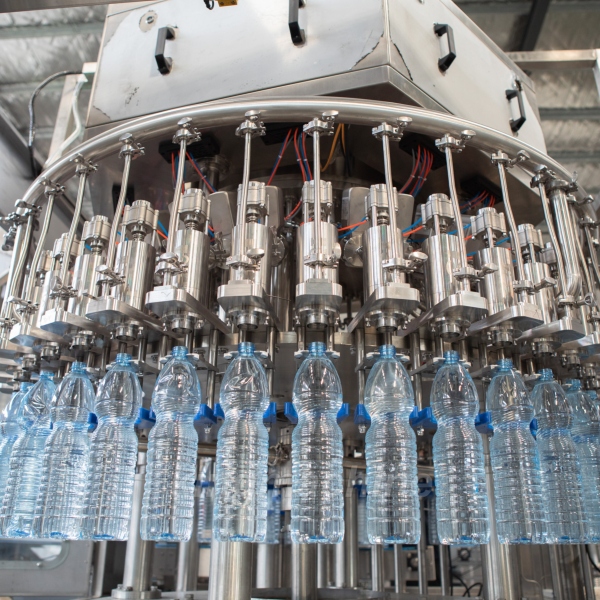

Beverages (Water, Juice, Soft Drinks)

Flow meter type filling machines are commonly used in the beverage industry. They are particularly suitable for water-based liquids like bottled water, juices, and soft drinks, where maintaining precise volumes is critical for both consumer satisfaction and regulatory compliance.

Liquid Cleaning Products

Liquid cleaning products such as detergents and household cleaners also require accurate filling to avoid overfilling or underfilling. Flow meter filling machines ensure that each container holds the exact quantity required, which is crucial for maintaining product consistency and meeting industry standards.

2. Oils

Edible Oils (Olive Oil, Sunflower Oil, etc.)

Edible oils are often high in value, and precision is important to avoid wastage. Flow meter filling machines are perfect for oils like olive oil, sunflower oil, and vegetable oil. Their ability to handle liquids with varying viscosities ensures that each container is filled accurately without loss or contamination.

Lubricants and Industrial Oils

Lubricants and industrial oils, which are often thick and viscous, benefit from the flexibility of flow meter technology. These machines ensure consistent fills even for high-viscosity liquids, making them ideal for products that require exact measurements in industrial applications.

3. Chemical Liquids

Acids, Solvents, and Other Chemicals

Handling corrosive or hazardous chemicals demands precision and safety. Flow meter filling machines excel at filling acids, solvents, and other chemicals by offering non-contact measurement, reducing the risk of spills or human exposure to dangerous substances. The accuracy of flow meters ensures that each chemical product is filled with the correct volume, which is crucial for safety and regulatory compliance.

Fertilizers and Agricultural Chemicals

Flow meter filling machines are ideal for liquid fertilizers, herbicides, and pesticides. These agricultural chemicals often require exact dosing to avoid underuse or overuse, which can have significant consequences on crop yield or safety. Flow meter technology ensures precise filling, helping manufacturers meet strict industry standards for chemical products.

4. Pharmaceutical and Medical Liquids

Liquid Medicines (Syrups, Solutions)

In the pharmaceutical industry, accuracy in liquid dosage is vital. Flow meter filling machines are widely used for filling liquid medications such as syrups and solutions, ensuring each container holds the exact dose required. This level of precision is essential to maintain product safety, efficacy, and compliance with health regulations.

Medical and Laboratory Fluids

Laboratory and diagnostic fluids, such as reagents or saline solutions, must be filled with extreme accuracy and often under sterile conditions. Flow meter filling machines ensure that the required volume of liquid is dispensed without compromising the integrity of the product. This precision is especially important in medical settings, where even minor deviations can have significant consequences.

5. Cosmetics and Personal Care Products

Shampoos, Conditioners, Lotions

Flow meter filling machines are well-suited for personal care products like shampoos, conditioners, and lotions. These products can vary in viscosity, and flow meters ensure that each container is filled to the correct level without wasting product or causing spillage. Their flexibility allows manufacturers to handle a range of viscosities with ease.

Perfumes and Fragrances

Perfumes and fragrances are often high-value liquids that require precise filling to maintain consistency in volume. Flow meter technology ensures that each bottle is filled with the exact amount, which is particularly important for premium products where precision and consistency are critical to maintaining brand reputation.

Factors That Make Flow Meter Filling Machines Ideal for Certain Liquids

1. Accuracy and Precision

Flow meter filling machines offer unmatched accuracy, ensuring that each product is filled with the exact amount of liquid. This is particularly important for high-value liquids, such as pharmaceuticals or perfumes, where even small deviations in volume can have significant financial or safety implications.

2. Flexibility in Viscosity Handling

Flow meters are versatile and can handle liquids with a wide range of viscosities, from thin water-like products to thick oils and lotions. This flexibility makes them ideal for manufacturers who deal with different types of liquids in their production lines.

3. Non-Contact Measurement

For hazardous or sensitive liquids, flow meter filling machines offer non-contact measurement, reducing the risk of contamination or spills. This feature is especially useful in industries such as pharmaceuticals and chemicals, where maintaining product purity is essential.

4. Adaptability to Different Containers

Flow meter filling machines can be easily adapted to handle various container sizes, making them suitable for industries with diverse packaging requirements. Whether filling small vials or large bottles, these machines offer the precision needed for different container types.

Applications of Flow Meter Filling Machines in Various Industries

Food and Beverage Industry

Flow meter filling machines are widely used in the food and beverage industry for products like water, juices, oils, and sauces. Their ability to handle both low and high-viscosity liquids makes them ideal for this sector.

Chemical and Industrial Applications

In the chemical industry, flow meter technology is essential for handling corrosive or hazardous liquids. Whether filling solvents, acids, or industrial lubricants, these machines ensure precise, safe filling.

Pharmaceutical and Medical Sector

Precision is critical in the pharmaceutical and medical fields. Flow meter filling machines provide the accuracy needed for filling liquid medicines, syrups, and medical solutions.

Cosmetics and Personal Care

Flow meter systems are also popular in the cosmetics industry, where products like shampoos, lotions, and perfumes require consistent and accurate filling to maintain product quality and branding.

Conclusion

Flow meter filling machines are ideal for a wide range of liquids, from water-based products and edible oils to chemicals, pharmaceuticals, and cosmetics. Their precision, versatility, and ability to handle various viscosities make them indispensable in many industries.

By choosing a flow meter filling machine, manufacturers can improve the efficiency, accuracy, and safety of their production lines, ensuring that each liquid product is filled to the exact specifications. Whether dealing with thin liquids like water or thick substances like industrial oils, flow meter technology offers the perfect solution for accurate and reliable filling.