News

Site Editor

Site

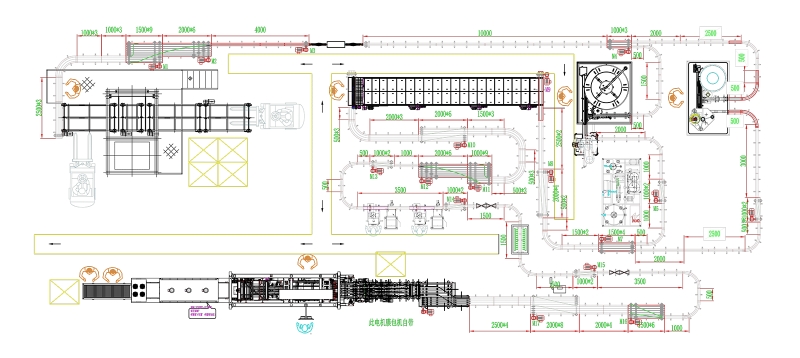

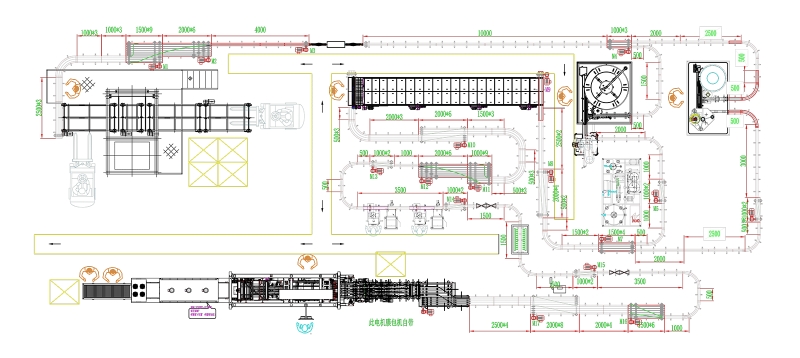

/uploads/image/694e24f48271f.png

Aluminum can filling machines are vital equipment in the beverage industry, streamlining the process of packaging a variety of drinks. Whether you’re bottling carbonated sodas, refreshing juices, or frothy beers, these machines offer efficiency and precision. Here’s a guide on how to use an aluminum can filling machine to fill different types of beverages effectively.

Site

/uploads/image/694e24f48271f.png

Aluminum can filling machines are vital equipment in the beverage industry, streamlining the process of packaging a variety of drinks. Whether you’re bottling carbonated sodas, refreshing juices, or frothy beers, these machines offer efficiency and precision. Here’s a guide on how to use an aluminum can filling machine to fill different types of beverages effectively.

How to Use an Aluminum Can Filling Machine for Different Beverages

Views: 1802

Author: Site Editor

Publish Time: 2024-09-11

Origin: Site

Aluminum can filling machines are vital equipment in the beverage industry, streamlining the process of packaging a variety of drinks. Whether you’re bottling carbonated sodas, refreshing juices, or frothy beers, these machines offer efficiency and precision. Here’s a guide on how to use an aluminum can filling machine to fill different types of beverages effectively.

1. Understanding the Types of Filling Machines

Before diving into the specifics, it’s crucial to understand the different types of filling machines available:

Carbonated Can Filling Machine: Designed specifically for beverages that contain carbon dioxide, like soda or sparkling water. These machines handle the pressure of carbonation and ensure that the cans are sealed properly to prevent gas escape.

Beer Can Filling Machine: Tailored for beer, which often requires precise temperature control and pressure management to maintain its quality and carbonation level.

Juice Can Filling Machine: Optimized for non-carbonated beverages such as fruit juices. These machines usually have features to handle thicker liquids and ensure proper hygiene.

Soda Can Filling Machine: Similar to carbonated filling machines but may come with additional settings for different types of sodas, including those with varying levels of carbonation.

2. Preparation Before Filling

Clean and Sterilize the Equipment: Ensure that the aluminum can filling machine is thoroughly cleaned and sterilized. This step is crucial to prevent contamination and maintain the quality of the beverage.

Set Up the Cans: Make sure the aluminum cans are pre-washed and ready for filling. They should be free from dust and debris to ensure a clean fill and proper sealing.

Adjust Machine Settings: Different beverages require different machine settings. Adjust the machine according to the type of beverage you are filling:

For carbonated beverages, set the pressure and carbonation levels.

For juices, adjust the filling speed and volume.

For beer, ensure the temperature settings are appropriate to maintain freshness.

3. Filling Process

Load the Cans: Place the aluminum cans into the machine’s loading area. Most modern machines have automated systems for loading cans, but manual loading may be required for some models.

Select the Beverage Type: Choose the beverage type from the machine’s control panel. This step ensures that the machine uses the correct filling parameters for the specific drink.

Initiate the Filling: Start the filling process. The machine will fill each can with the specified volume of beverage. For carbonated drinks, the machine will manage the carbonation levels to prevent foaming and spillage.

Seal the Cans: After filling, the cans will move to the sealing station. The machine will apply the can lids and seal them tightly to prevent any leakage and preserve the drink’s quality.

4. Post-Filling Procedures

Inspect the Filled Cans: Conduct a quality check on the filled and sealed cans. Ensure that there are no leaks, improper seals, or inconsistent fill levels.

Clean the Machine: After completing the filling process, clean the machine thoroughly. This prevents cross-contamination between different types of beverages and maintains the equipment in good working condition.

Perform Routine Maintenance: Regular maintenance of the aluminum can filling machine is essential for its longevity and optimal performance. Follow the manufacturer’s guidelines for routine checks and servicing.

In conclusion, using an aluminum can filling machine efficiently requires an understanding of the specific needs for different types of beverages. By properly preparing the equipment, adjusting settings, and maintaining the machine, you can ensure high-quality filling for carbonated sodas, beer, juices, and more. Whether you're in a small-scale operation or a large production line, mastering these steps will lead to smooth and successful beverage packaging.