News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

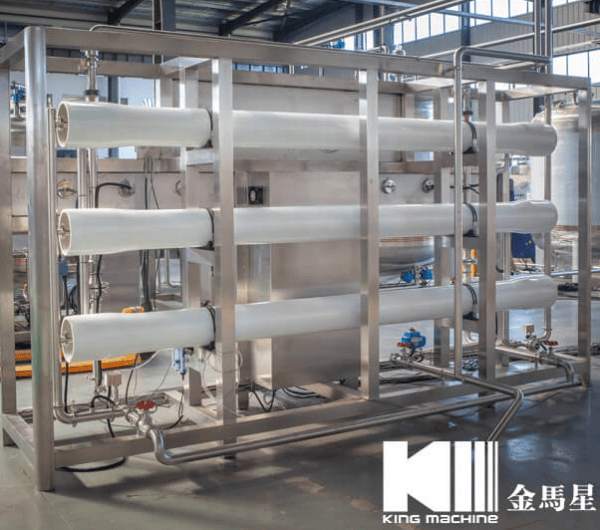

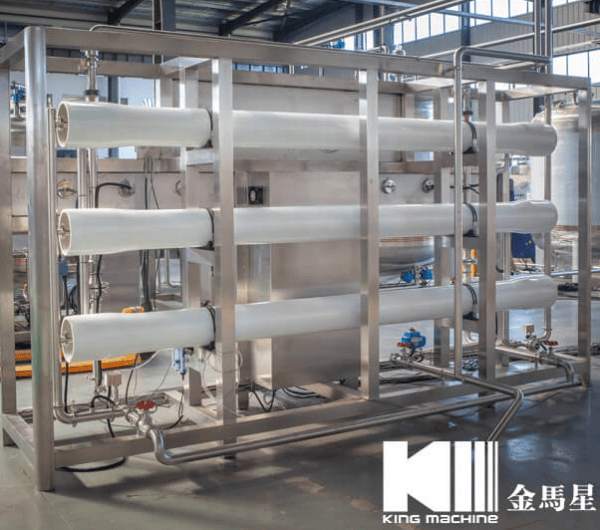

Consequently, through this post, we will learn how industrial water purification systems contribute to the daily water savings of thousands of liters.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

Consequently, through this post, we will learn how industrial water purification systems contribute to the daily water savings of thousands of liters.

The Benefit of Installing Water Treatment Plants in Food/Beverage Industries

Views: 1234

Author: Site Editor

Publish Time: 2022-12-14

Origin: Site

Everyone's existence revolves around water in some way. Water is necessary for both living creatures and non-living things. Every day, our companies use tons of water in production and other operations.

Every day, heavy industry and domestic sewage produce hundreds of gallons of water waste. People don't pay much attention to wastewater treatment, whether consciously or unconsciously.

It impacts the environment as well as the neighboring residents, including the people, plants, and animals. In addition, businesses can gain from reusing treated water in product manufacturing.

Consequently, through this post, we will learn how industrial water purification systems contribute to the daily water savings of thousands of liters.

Benefits of Industrial Water Treatment

The treatment method is broken down into several phases to guarantee high-quality water. Installing wastewater treatment facilities in the beverage and alcohol sectors is crucial for reaping numerous benefits.

1. Decrease in waste

Prior to having to release the water into the environment, the wastewater treatment plants are in charge of purifying it by removing a sizable amount of garbage. This miraculously lowers the health risks associated with the increased environmental pollutants.

2. Energy production

A huge amount of biodegradable material is found in the sludge that is collected throughout the treatment procedure. Methane is produced during the anaerobic method used to treat this.

The process produces methane gas, which is utilized to create electricity that is then used to power the wastewater treatment facility.

3. Production of fertilizers

The biodegradable components of wastewater can be converted into organic fertilizers for use in agriculture to boost crop yields. As a result, fewer chemical fertilizers are used.

4. Produces Energy

Water is the source of electricity, right? The energy generated while purifying the water allows the industrial water treatment facility to run fully on that energy.

Yes, energy can be generated whilst the water is being purified. The residual electricity can also be sold to the national grid for widespread use.

5. Reusable Water

This makes it clear that wasting even wastewater harms the environment. Therefore, if there is any water that, despite treatment, cannot be used for consumption, it should be treated so that it won't harm the environment.

In addition, cleaning the wastewater at an industrial water treatment facility might yield clean water for reuse. If necessary, it can also be made fit for human consumption.

How The Entire Process of Treating Water Is Carried Out

So let's begin;

1. Industry water purification

Goes through the screening, coagulation/flocculation, filtering, and disinfection processes, which are the four basic steps.

2. Screening

This procedure involves passing the source water through a screen, which keeps large particles out of the water so they won't obstruct the subsequent purification step.

3. Coagulation/Flocculation

In this procedure, the water is mixed with a certain chemical. The chemical separates the water from the tiny, sticky particles. After that, the waste materials in the water are removed.

4. Filtration

The process that involves passing water through numerous different types of filters is the next and most challenging step. The entire floc is left in the infiltration media during this procedure, and only pure water is transported for the next step.

5. Disinfection

The water is finally gathered in the disinfection tank, where chlorine is added to kill off any harmful bacteria. The harmful bacteria in the water are eliminated by the disinfectant, making the water reusable.

Contact Us for Your Premium Water Treatment Equipment

We create water treatment facilities that guarantee to clean wastewater and render it usable. Technically speaking, the water treatment facilities are made to reuse beverage and alcoholic beverage water.

Get in touch with us to order water treatment equipment and to learn more.