News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

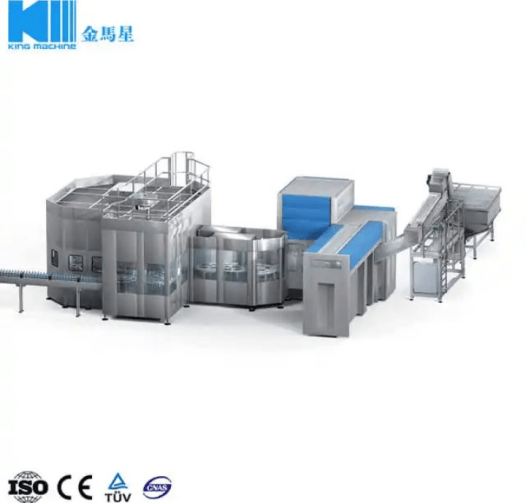

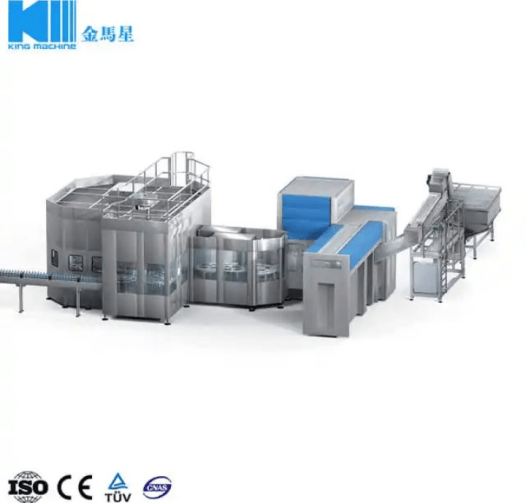

When buying a bottling device, today’s dairy and beverage producers want a machine that is flexible, easy to use, cost-effective, and multitasking. If that's the type of machine you also want, then a Blowing-filling-capping machine is the perfect choice for you.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

When buying a bottling device, today’s dairy and beverage producers want a machine that is flexible, easy to use, cost-effective, and multitasking. If that's the type of machine you also want, then a Blowing-filling-capping machine is the perfect choice for you.

What Are The Benefits of Blowing-Filling-Capping Machine?

Views: 1244

Author: Site Editor

Publish Time: 2022-11-14

Origin: Site

When buying a bottling device, today’s dairy and beverage producers want a machine that is flexible, easy to use, cost-effective, and multitasking. If that's the type of machine you also want, then a Blowing-filling-capping machine is the perfect choice for you.

Most machines have features that are particularly vital for low-quantity manufacturing scenarios (i.e., 8,000 bottles per hour or fewer) whilst labor, floor space, and capital device budgets tend to be high. However, the bottling-filling-capping machine lowers your overall cost of production.

In this article, we will walk you through the several benefits of the bottling-filling-capping machine that makes it fit for industrial production, especially in the beverage industry.

Space Saving With Preforms

The bottling-filling-capping machine subjects the bottle to preliminary shaping to form compact structures known as preforms.

Storing empty bottles is a logistical task for dairy and beverage processors since they occupy a large area. Preforms, on the opposite hand, use 10x much less area than fashioned bottles. In fact, a single pallet can keep as many as 10,000 preforms.

For this reason, the bottling-filling-capping machine is designed to blow preforms, permitting you to store them in areas where they won't occupy much space.

All-in-one Solution Reduces Troubleshooting

Manufacturers who buy separate machines for blowing, filling, and capping bottles have a tendency to spend extra time troubleshooting because each of the OEMs uses distinctive interfaces. However, the bottling-filling-capping machine may be operated through a single character. This extremely smooth filling solution has been examined and subtle to assure smoother operation.

Versatile Production

The bottling-filling-capping machine can accommodate a huge variety of containers from 150ml to 1.5l bottles with 2 necks options.

This machine offers an additional benefit, it consists of short and clean changeovers, permitting dairy and beverage processors to bottle an extensive variety of products, which include dairy products, fruit juices, soups, smoothies, dietary drinks, coffees, teas, fermented drinks, and much more.

Logistical Benefits

In addition to decreased troubleshooting, the all-in-one answer is compact and occupies a smaller footprint for your plant.

Additionally, due to the fact that preforms do now no longer occupy a big quantity of area for your facility, they permit dairy and beverage processors to have astonishing outputs. For each preform truckload that comes in, up to 8 crammed bottle truckloads cross out.

Also, it is easier to transport your all-in-one bottling-filling-capping machine from the manufacturing company to your industry than it is to transport separate machines performing each of the functions of the bottling-filling-capping machine.

Purchase High-quality Bottling-filling-capping Machines from us

Perhaps you need a high-quality bottling-filling-capping machine but you're worried about getting a reputable supplier of this product. Sure, many unauthorized manufacturers are available but you can still get the best product from a reputable manufacturing company like King Machine.

King Machine, being a reputable and experienced manufacturer and supplier of premium bottling-filling-capping machine, assures you of getting high-quality products. We have 5-star reviews from our, which affirm our integrity. So, click here to check out our best collections now.