News

Site Editor

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

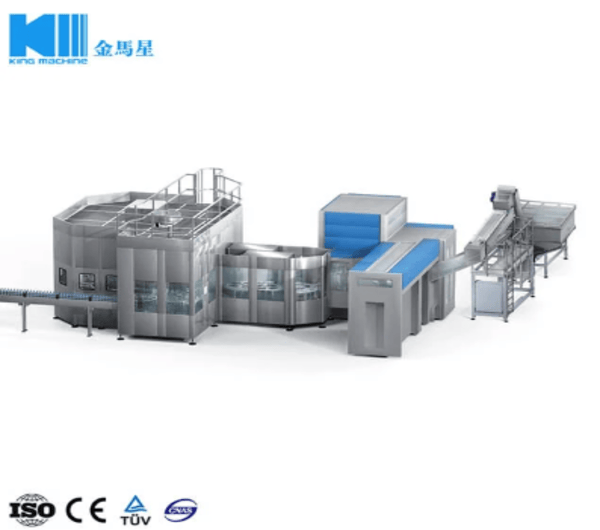

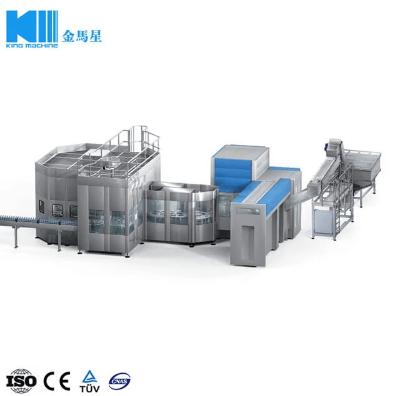

This article will give you a detailed insight into the benefits of choosing a blowing-filling capping machine for your liquid packaging operations.

Site

https://king-machine.usa72.wondercdn.com/uploads/image/6454bbd2e50a2.png

This article will give you a detailed insight into the benefits of choosing a blowing-filling capping machine for your liquid packaging operations.

Why Blowing Filling Capping Machine is Your Best Option

Views: 1206

Author: Site Editor

Publish Time: 2022-11-10

Origin: Site

Water is a very important class of nutrients that is responsible for the daily survival of man, irrespective of your age, financial capacity, or status. The consumption of water and other liquids such as juice is achieved through the use of certain materials of which plastics are an integral material often used.

You may be inquisitive to ask how these bottles achieve the desired size and shape requested by the person that needs them. The action is performed through the use of a machine. As an added advantage, a blowing filling capping machine co

This article will give you a detailed insight into the benefits of choosing a blowing-filling capping machine for your liquid packaging operations.

What is a Blowing Filling Capping Machine?

A blowing-filling capping machine is a three-fold operations machine that combines the actions of blowing, filling as well as capping and functions as one. The working operation is straightforward.

After extrusion has taken place to form parison, which is in a tube-like form of the envisaged bottle shape, the parison is then passed into an enclosure when air is blown into it under pressure resulting in the expansion of the bottle into the appropriate and desired shape.

Through a conveyor, the formed plastic bottles are then passed to the section where they will be filled with the desired liquid product after which they pass through to the section where a cap will be used to cover the product-filled bottles.

Benefits of Choosing Blowing Filling Capping Machine

1. Improved Production Rate

With the evolution of the three-in-one operational machine, you do not necessarily wait for each process to complete individually before proceeding with the next stage of the process.

Every process is automatic which ensures that there is no delay in production, hence improving the rate of the resulting products.

2. Consistency in Operation

The blowing filling capping machine produces uniform sets of plastics for every batch of production.

With this machine, you can rest assured that there are no differences in size, material composition, or shape of the resulting packaging bottle.

3. Reduced Cost of Management and Maintenance

Fact is told, the more machines you have, the more your expenses are when it comes to machine management and maintenance.

Having just one machine that functions multipurpose is a good way to reduce costs that are associated with machine maintenance.

Partner with us for Premium Quality Blowing Filling Capping Machine

It is no doubt that every industry wants a manufacturing process that reduces worries regarding any aspect of the production process. This has resulted in an ever-increasing need for the blowing filling capping machine by many industries that deal with the use of plastic bottles.

Therefore, in case you are ready to get yours, you can always reach out to us and let us discuss a budget that suits your pocket capacity.

Contact us today for your premium quality blowing filling capping machine at prices that will not break the bank.