|

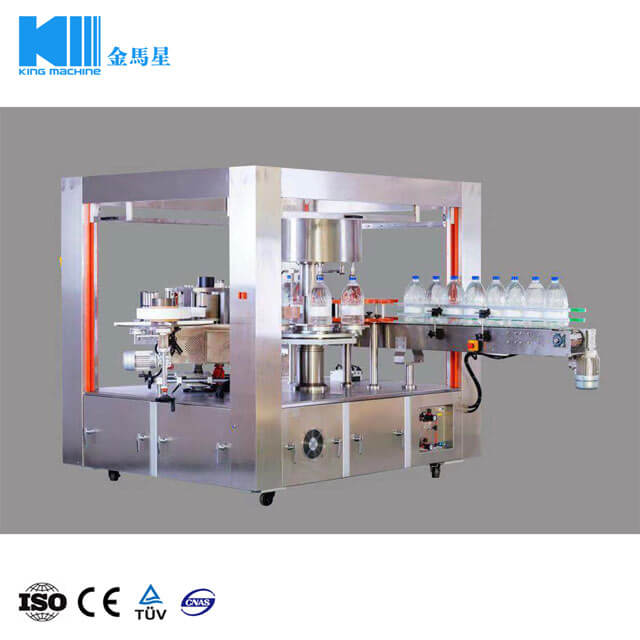

Hot Melt Glue Labeling Machine

This series of hot melt glue labeling machine can be used for round bottles, square bottles, flat bottles and other special-shaped bottles labeling. (Different products have different models) |

|

Label station

label station forward and backward movement, up and down, tilt Angle, can be multi-dimensional adjustment. (The whole station adopts Krons structure, stable and reliable operation, convenient operation, no jitter phenomenon in high-speed operation, to ensure the accuracy of labeling) |