1.1 New Auto Preform Unscrambler System

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will

warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

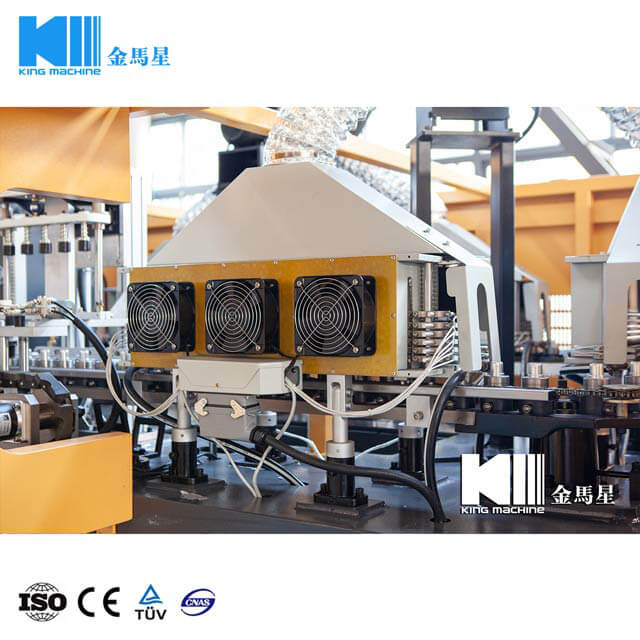

1.2 New Heating System

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

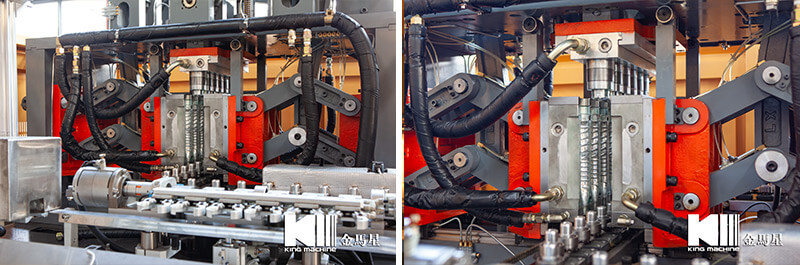

1.4 Servo Technology Innovation On Clamping System & Stretching

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

1.5 Easy To Change Bottle Shape

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the

condition of same bottleneck diameter.

1.6 Intelligent Human-Machine Interface

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.