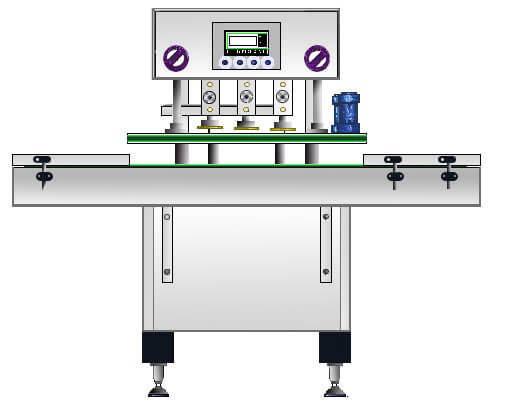

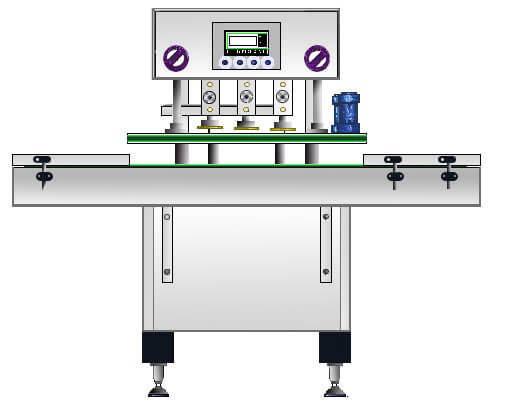

GX-200 capping machine is a new generation of capping machine designed and manufactured by our company for the production process of the tablet and the automatic capping process. The utility model is different from the prior rotary capping machine, and overcomes the shortcomings of the speed of the rotary capping machine, such as the slow speed of the screw cap, the tight cover of the screw cap and the small range of application. In the design of the machine, a new process is adopted, such as linear entry, automatic falling cover and uninterrupted screw capping.

1:A widely used shock drop mechanism is used in the design of drop covers, which is suitable for most cap products.

2:In the design of the drop cover, the most advanced lifting cover device in the industry is adopted to avoid the noise of oscillation and fall cover, and the output is also greatly improved.

| Model | GX200 high speed capping machine |

| Capacity (B/M) | 50~200 |

| Suitable for bottle diameter(mm) | Φ30~120 |

| Suitable for cap diameter(mm) | Φ20~50 |

| Overall size(mm) | 1800×1000×1500 |

| Capping device (optional) | Lifting type falling cover device | Lifting type falling cover device |

| Cap elevator size(mm) | 1080×600×1860 | 800×600×1700 |

| Weight (kg) | 850 |

| Motor total power(w) | 1300 |

| Voltage | 220V / 50~60Hz |

Component:

| Name | Component | Manufacture | Note |

GX-200 Capping machine | Inverter | DELTA |

|

| Photo-cell | Korea autonics |

|

| Touch Screen | Touch Win |

|

| CPU | USA ATMEL |

|

| interface chip | USA MEX |

|

| PLC | DELTA |

|

| Special rubber parts for rotary cover | Shanghai |

|

| Motor | JSCC |

|

| Stainless Steel | Korea | 304 |

| Frame Corn Steel | Shanghai Bao Steel |

|

| Aluminum alloy parts | LY12 |

|

Draft:

Suit for bottle size:

Q:How about the spare parts?

A:We will send one year enough easy broken spare parts together with the machines,shipping together.

During the warranty time,we will supply the spare parts with our cost including the delivery fees.

Q:How long time for installation?

A:According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Q:How to install my machines when it arrives?how much the cost?

A:We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Customer pay airtickets go and back,accommodation and USD80/day/person.

Q:When can I get my machine after I paid?

A:Normally production time is around 30-60days,the exactly depend on what kind of machine you order.The shipping time is based on your destination port.

Q:What’s your guarantee or the warranty of the quality if we buy your A1:machines?

A:We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q:Are you a trading company or a manufactory?

A:We are a manufactory, we supply the factory price with good quality, welcome to visit !