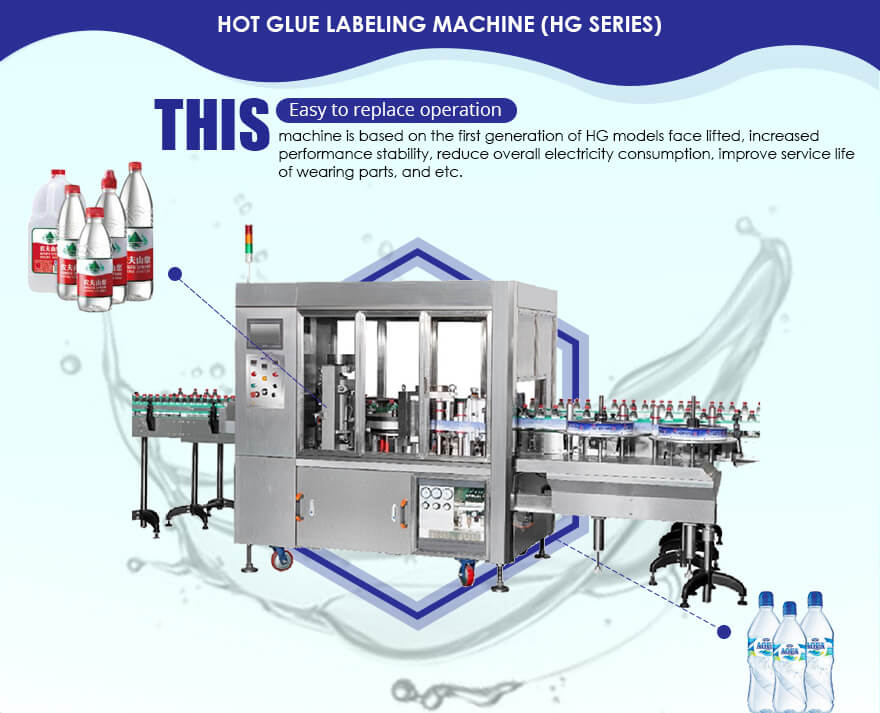

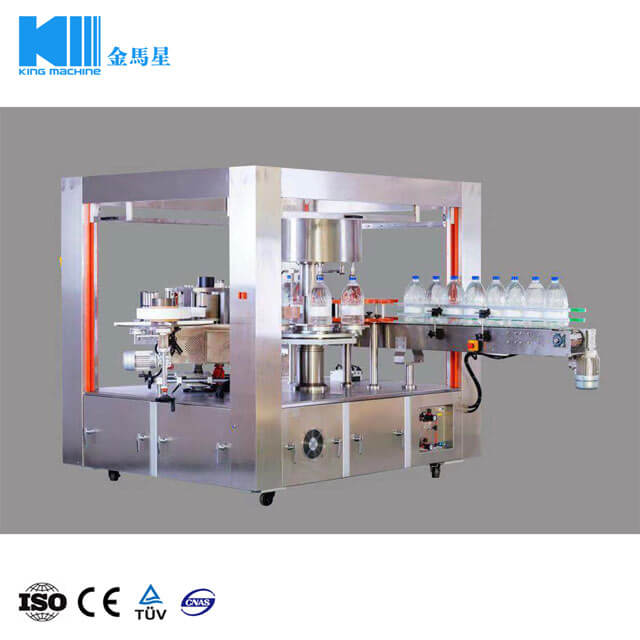

HG1 series Hot Glue Labeling Machine For Plastic Bottle is based on the first generation of HG models face lifted, increased performance stability, reduce overall electricity consumption, improve service life of wearing parts, and etc. Bottle labeling location diameter not greater than 70MM's production line to meet a round bottle labeling requirements, applicable to the labeling for empty bottle and after filling bottle. Stable production speed of up to 200 bottles per minute; 12,000 bottles per hour. Applicable to customers: only a circular bottle-type, production volume, high strength production company takes a long time.

1. Operation and maintenance is simple;

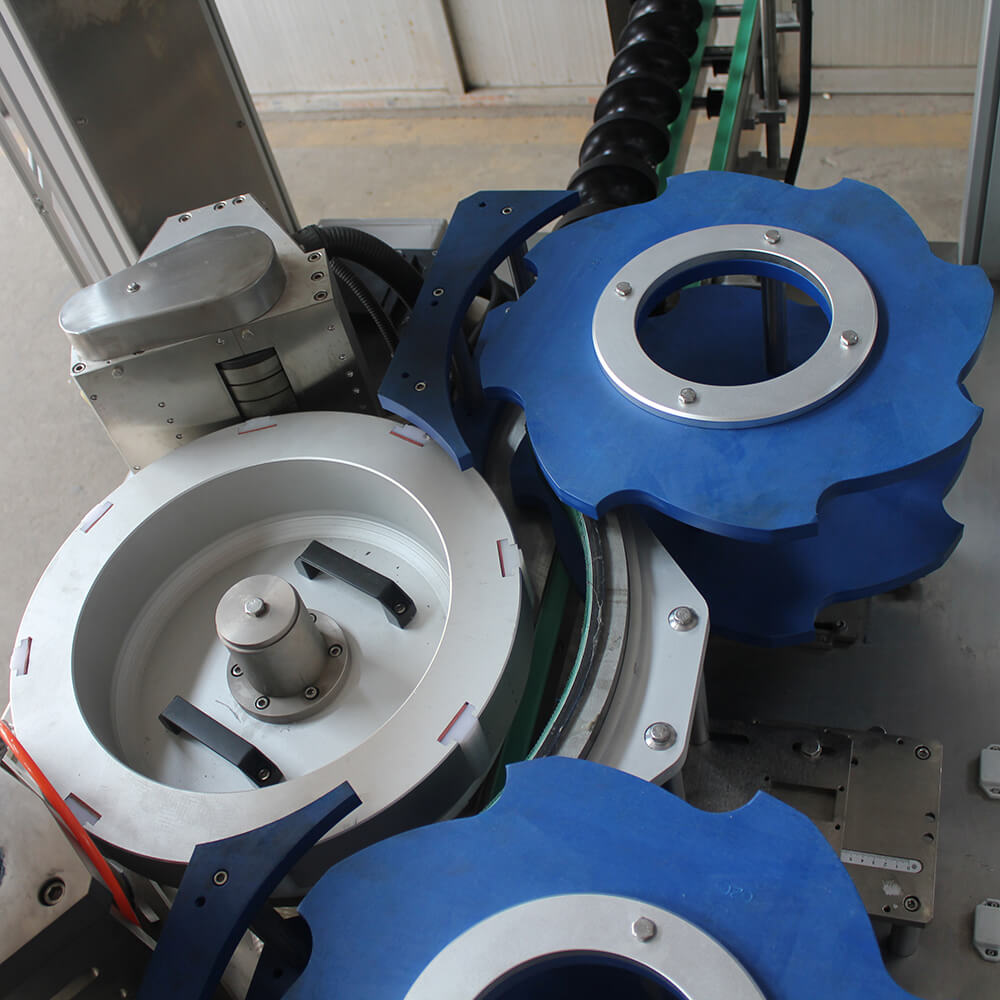

2. Optimal structural design to minimize number of wearing parts, improve its service life;

3. Configuration of different bottle and label parts, easy to replace operation;

4. Dynamic, cutter adjustment process simple, good cutting performance, high service life;

5. Through the label conveying mechanism and optimum design of the control system, adaptable to labels.

Hot Glue Labeling Machine For Plastic Bottles are mainly used in the beverage industry, food, condiment, cosmetic and other industries are also widely used.

Model | HG-B-8K | HG-B-12K | HG-B-18K |

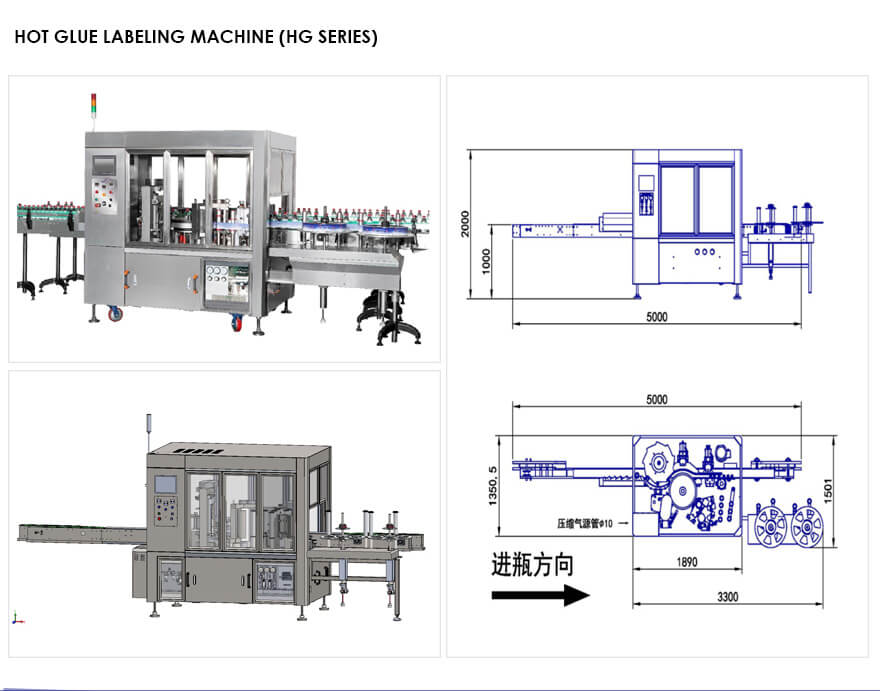

Size of equipment | 5000L*1600W*2000H(mm) | 5000L*1600W*2000H(mm) | 5200L*1600W*2000H(mm) |

With conveyor length | 5M | 5M | 5M |

Weight | 2tons | 2T | 2T |

Inside label roller | 6inch | 6inch | 6inch |

Suitable bottle size dia | 55-120mm | 55-120mm | 55-120mm |

Effective | Not less 95% working continually 8hours | Not less 95% working continually 8hours | Not less 95% working continually 8hours |

Precision | ±2mm | ±2mm | ±2mm |

Defective rate | Less than 1‰ | Less than 1‰ | Less than 1‰ |

Speed | Stable capacity not less 135bpm | Stable capacity not less 300bpm | Stable capacity not less 300bpm |

Power Supply | 220/380V 3ph | 220/380V 3ph | 220/380V 3ph |

Consumed Power | 9KW | 9KW | 9KW |

Air Consumption | 1Mpa | 1Mpa | 1Mpa |