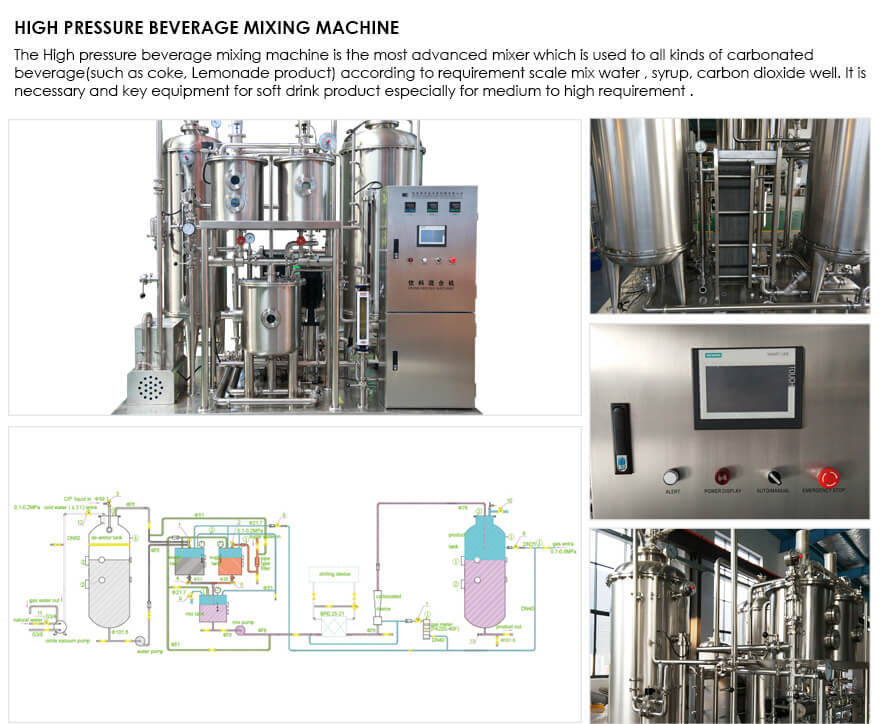

1.The machine, after the adoption of advanced technologies in the chemical industry—static mixer (carbonizer), features large area of gasquid mass transfer, small resistance loss, high efficiencym, low energy consumption, and simple structure. It also adopts the multi-stage centrifugal pump with reliable performance and low noise, guaranteeing the performance of the whole machine.

2.The mixing proportion is accurate and easy for adjustment. With no need of parts replacement, the machine can realize the quick output adjustment and the proportion of syrup and water.

3.The machine, by use of CO2 reflux deoxidation, not only saves CO2, but also achieves the objective of deoxidation and makes the deoxidation water have better pre-carbonation effects.

4.The machine is convenient to adjust the gas content. According to the requirements of beverage gas content, the adjustment can be done through proper operation.

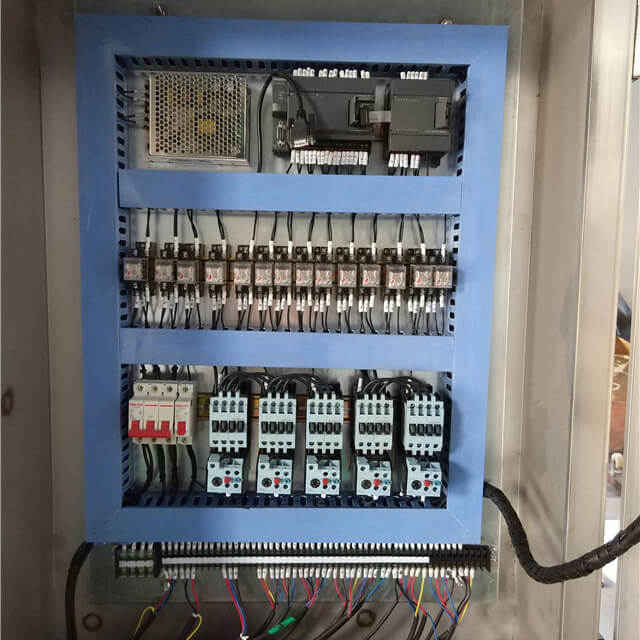

5.The machine has perfect automatic control system, featured by coordinate action, simple structure, continuous production, and high automation.

The machine is fitted with an in-place cleaning technique flow with reasonable structure, convenient for chemical disinfection, heat disinfection, and clear water washing and in compliance with Food Hygiene Law of the People's Republic of China.

Description of the machine:

QHS series drink mixer is designed and made for improving the proportion of water, syrup and carbon dioxide. It adopts foreign advanced technology—static mixer to lighten water layer, increase carbonizing time, assure mixing result and deoxying. It adopts high-quality water pump and

SEIMENS electrical equipment and other parts to form complete automatic control system. It has coordinating action, beautiful appearance, convenient washing, high automatic level and other

advantages. It is suitable for mixing all kinds of drink, such as soda water, fruit juice, cola and other soft and hard drink.